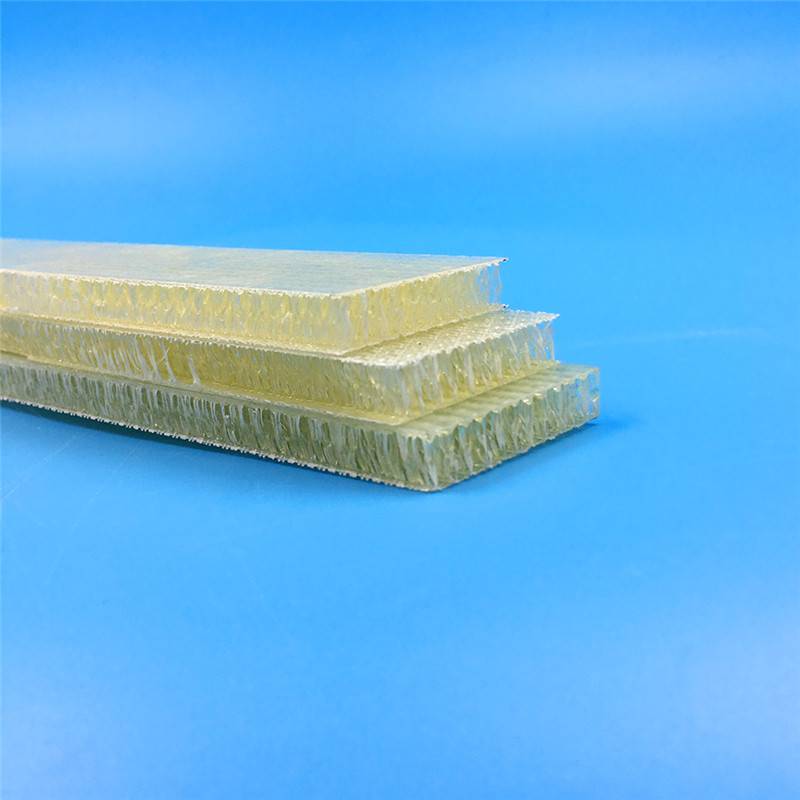

Iphaneli ye-3D FRP ene-resin

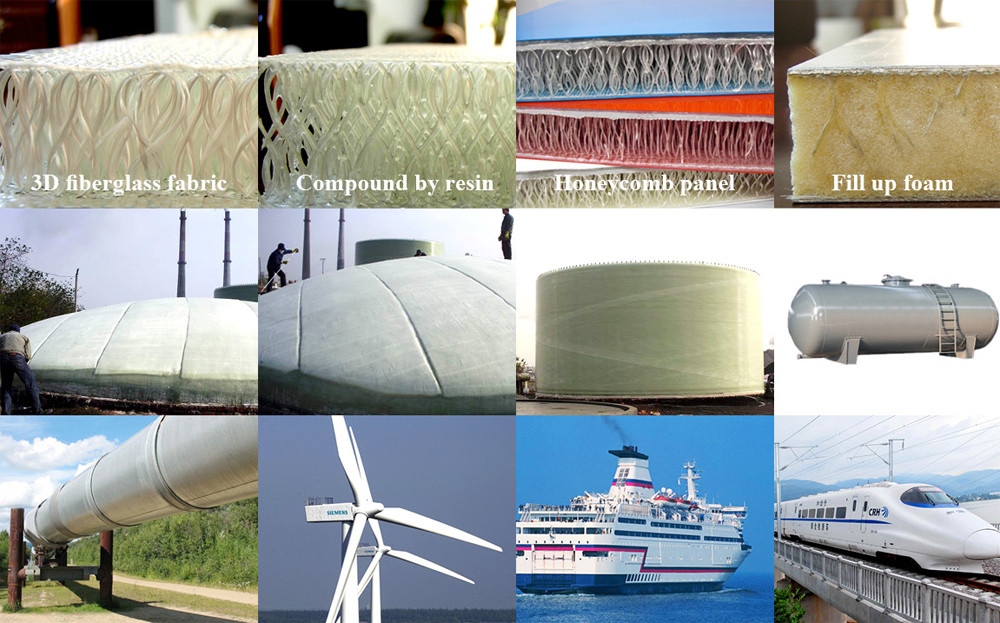

Ilaphu le-3-D Fiberglass Woven linokudityaniswa neeresini ezahlukeneyo (i-polyester, i-Epoxy, i-Phenolic njl.njl.), emva koko imveliso yokugqibela yiphaneli ye-3D composite.

Inzuzo

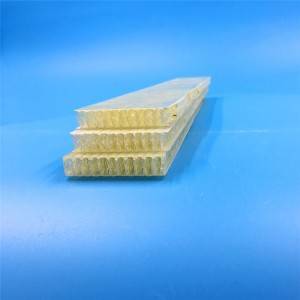

1. ubunzima obuphantsi bur amandla aphezulu

2. Ukumelana okukhulu nokuqhekeka kwe-delamination

3. Uyilo oluphezulu – ukusebenziseka lula

4. Isithuba phakathi kwee-deck layers zombini sinokuba nemisebenzi emininzi (Sifakwe ii-sensors kunye nee-wire okanye sifakwe i-foam)

5. Inkqubo elula nesebenzayo yokubopha ilamination

6. Ubushushu kunye nobushushu besandi, Ayitshisi, Ingathuthwa ngamaza

Isicelo

Inkcazo

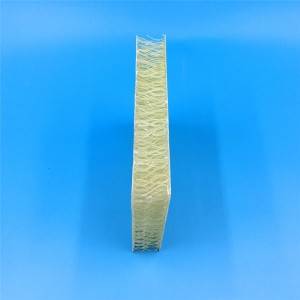

| Ukuphakama kweNtsika | mm | 4.0 | 6.0 | 8.0 | 10.0 | 12.0 | 15.0 | 20.0 | |

| Uxinano lweWarp | ingcambu/10cm | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Uxinano lweWeft | ingcambu/10cm | 96 | 96 | 96 | 96 | 96 | 96 | 96 | |

| Ubuninzi bobuso | Amalaphu e-3-D spacer | kg/m2 | 0.96 | 1.01 | 1.12 | 1.24 | 1.37 | 1.52 | 1.72 |

| Amalaphu e-3-D spacer kunye nokwakhiwa kwesandwich | kg/m2 | 1.88 | 2.05 | 2.18 | 2.45 | 2.64 | 2.85 | 3.16 | |

| Amandla okuThanda aGqibeleleyo | I-MPa | 7.5 | 7.0 | 5.1 | 4.0 | 3.2 | 2.1 | 0.9 | |

| Amandla okucinezela agudileyo | I-MPa | 8.2 | 7.3 | 3.8 | 3.3 | 2.5 | 2.0 | 1.2 | |

| Imodulus ecinezelekileyo ethe tyaba | I-MPa | 27.4 | 41.1 | 32.5 | 43.4 | 35.1 | 30.1 | 26.3 | |

| Amandla okuGcoba | I-Warp | I-MPa | 2.9 | 2.5 | 1.3 | 0.9 | 0.8 | 0.6 | 0.3 |

| I-Weft | I-MPa | 6.0 | 4.1 | 2.3 | 1.5 | 1.3 | 1.1 | 0.9 | |

| Imodulus yokucheba | I-Warp | I-MPa | 7.2 | 6.9 | 5.4 | 4.3 | 2.6 | 2.1 | 1.8 |

| I-Weft | I-MPa | 9.0 | 8.7 | 8.5 | 7.8 | 4.7 | 4.2 | 3.1 | |

| Ukuqina Kokugoba | I-Warp | N.m2 | 1.1 | 1.9 | 3.3 | 9.5 | 13.5 | 21.3 | 32.0 |

| I-Weft | N.m2 | 2.8 | 4.9 | 8.1 | 14.2 | 18.2 | 26.1 | 55.8 | |

Qaphela: Isalathisi sokusebenza esingentla senzelwe ulwazi kuphela, ngokusekwe kwiimfuno zokusebenza zomsebenzisi, isakhiwo sokuqinisa ilaphu le-3D spacer sinokuyilwa.