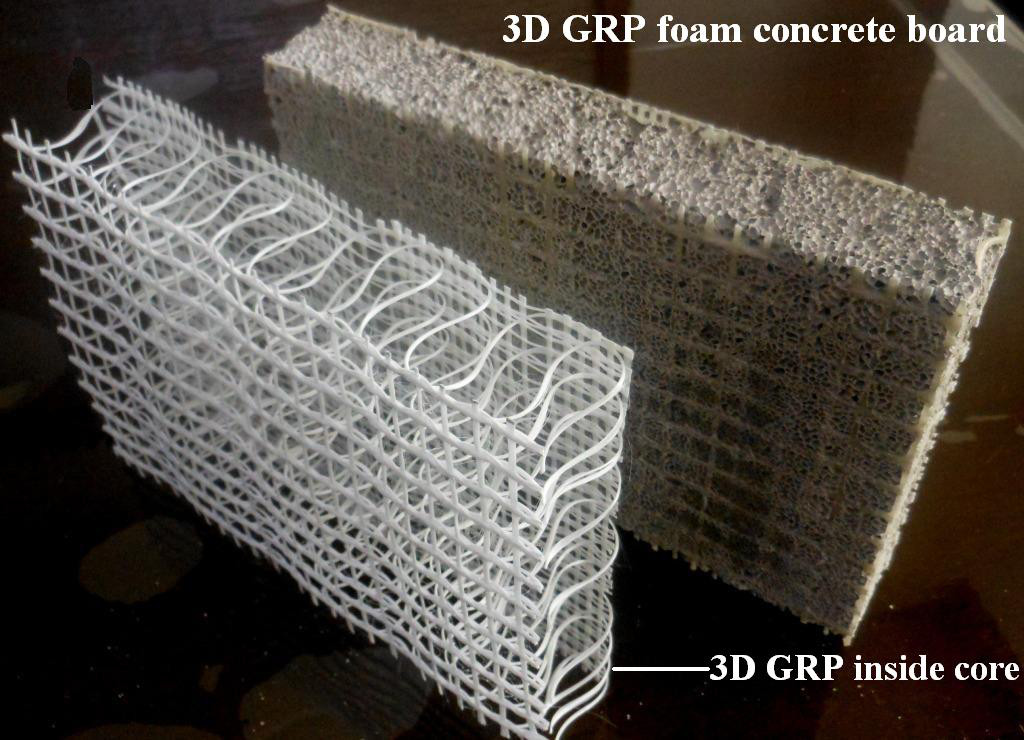

I-3D Ngaphakathi Komongo

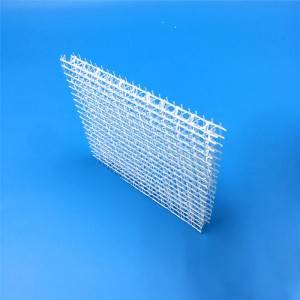

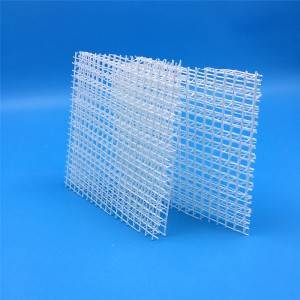

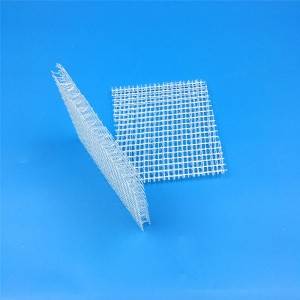

Ibhrashi ye-3D GRP yangaphakathi eneglu, emva koko i-molding elungisiweyo. Okwesibini yifake kwi-mold kwaye i-foam. Imveliso yokugqibela yibhodi yekhonkrithi ye-3D GRP foam.

Inzuzo

Sombulula ingxaki yesamente yefoam yendabuko: amandla ayo aphantsi, abuthathaka, kulula ukuwaqhekeza; phucula kakhulu amandla okutsala, ucinezelo, amandla okugoba (ukutsalwa, amandla okucinezela ayengaphezulu kwe-0.50MP).

Ngefomula yefoam eguquliweyo, ukuze ifoam ibe nokusebenza ngcono kokugquma ubushushu, inciphise ukufunxwa kwamanzi. Yeyona nto ifanelekileyo yokugquma isakhiwo ekumgangatho we-A1, ubomi obufanayo nesakhiwo.

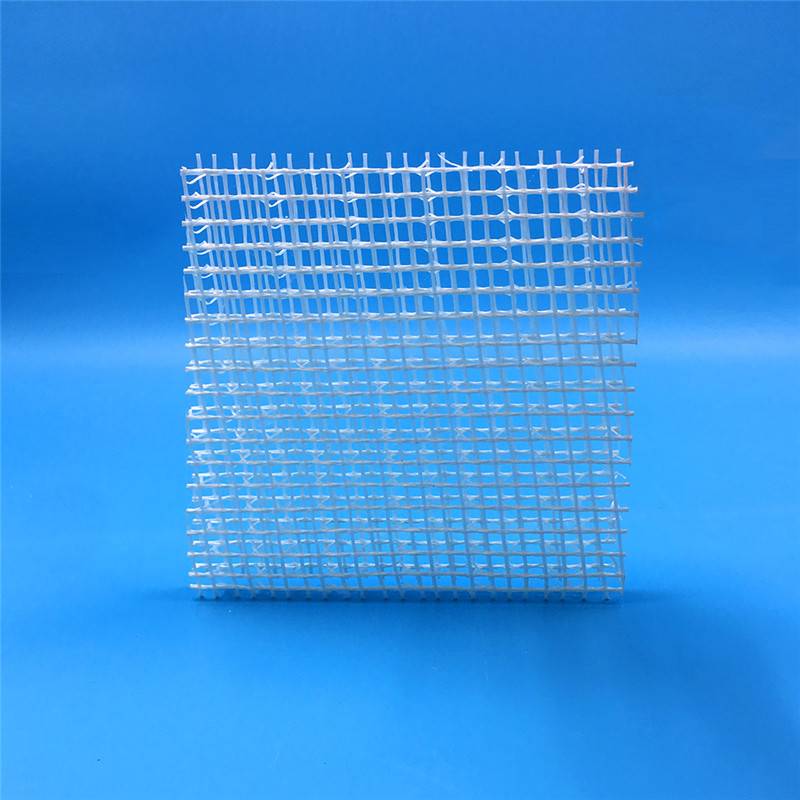

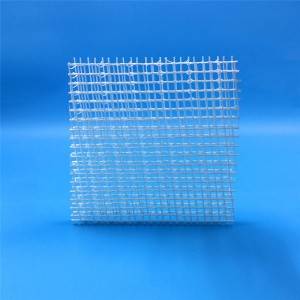

Ububanzi obuqhelekileyo yi-1300mm

Ubunzima 1.5kg/m2

Ubungakanani be-mesh: 9mm * 9mm

Isicelo

Indlela yokubrasha i-resin kwilaphu le-3D

1. Ukuxuba i-resin: Ngokuqhelekileyo sebenzisa ii-resin ezingagcwaliyo kwaye kufuneka wongeze i-agent yokunyanga (i-resin eyi-100g kunye ne-agent yokunyanga eyi-1-3g)

2. Umlinganiselo we-resin kwilaphu yi-1:1, umzekelo, ilaphu eli-1000g lifuna i-resin eyi-1000g.

3. Ukukhetha iqonga lokusebenza elifanelekileyo kwaye ilaphu kufuneka lifakwe iwax kumphezulu weqonga lokusebenza (ngenjongo yokususa uthuli)

4. Ukubeka ilaphu kwiqonga lokusebenza.

5. Ngenxa yokuba ilaphu ligoqeka kwiityhubhu zephepha, iintsika eziphambili ziya kuthambekela kwicala elinye.

6. Siza kusebenzisa imiqulu ukubrasha i-resin kwicala elithambekileyo lelaphu ukuze imicu yelaphu ingene.

7. Emva kokuba imicu yelaphu ingeniswe ngokupheleleyo, singatsala umaleko ongaphezulu welaphu kwicala elichaseneyo size sigcine lonke ilaphu lime nkqo.

8. Ingasetyenziswa xa iphelile ngokupheleleyo.