Iimathi zeFiber zeGlasi

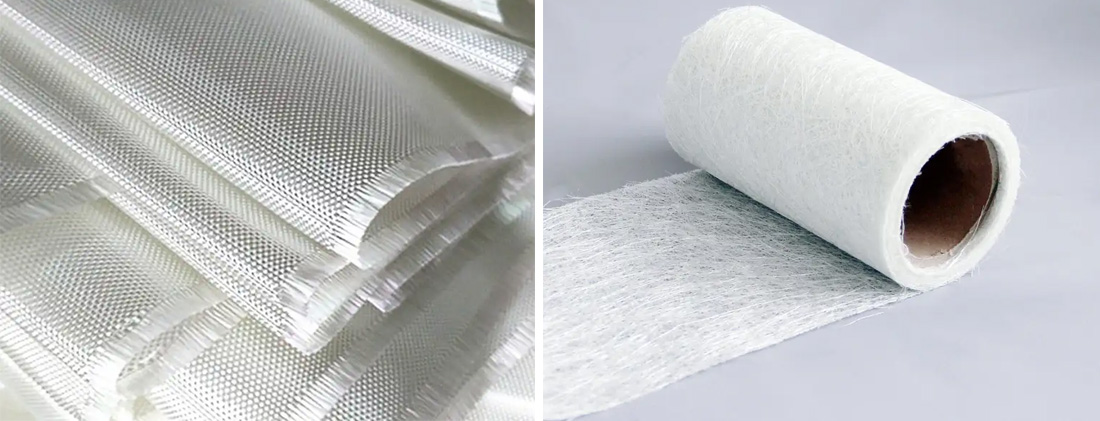

1.I-Crand Mat eqoshiweyo (CSM)Ukuzulazula ngefayibha yeglasi(ngamanye amaxesha ikwajikeleza rhoqo) isikwa ibe bubude obuyi-50mm, ibekwe ngokungacwangciswanga kodwa ngokulinganayo kwibhanti ye-conveyor mesh. Emva koko kufakwa i-emulsion binder, okanye i-powder binder ifafazwa, kwaye izinto ziyafudunyezwa kwaye zicocwe ukuze zenze i-strand mat eqoshiweyo. I-CSM isetyenziswa kakhulu ekubekeni ngesandla, ekwenzeni iiphaneli eziqhubekayo, ekubumbeni iidayi ezihambelanayo, nakwiinkqubo ze-SMC (Sheet Molding Compound). Iimfuno zomgangatho we-CSM ziquka:

- Ubunzima bendawo efanayo ububanzi.

- Ukusasazwa okufanayo kwemicu enqunqiweyo kumphezulu we-mat ngaphandle kwemingxuma emikhulu, kunye nokusasazwa okufanayo kwe-binder.

- Ukuqina okuphakathi komati owomileyo.

- Iipropati ezintle kakhulu zokumanzisa i-resin kunye nokungena kwayo.

2.I-Continuous Filament Mat (CFM)Iifilamenti zefayibha yeglasi eziqhubekayo ezenziwe ngexesha lenkqubo yokuzoba okanye ezivulekileyo kwiipakethe ezijikelezayo zibekwe phantsi kwipateni yesibalo-esibhozo kwibhanti ye-mesh ehamba rhoqo kwaye zibotshelelwe nge-powder binder. Ekubeni iifayibha kwi-CFM ziqhubeka, zibonelela ngokuqiniswa okungcono kwizinto ezidityanisiweyo kune-CSM. Isetyenziswa kakhulu kwiinkqubo ze-pultrusion, i-RTM (Resin Transfer Molding), i-pressure bag molding, kunye neenkqubo ze-GMT (Glass Mat Reinforced Thermoplastics).

3.I-Mat yokugqumaIimveliso ze-FRP (iFiber Reinforced Plastic) zihlala zifuna umaleko womphezulu otyebileyo we-resin, odla ngokufumaneka ngokusebenzisa umaleko womphezulu weglasi ephakathi kwe-alkali (iglasi ye-C). Njengoko le mat yenziwe ngeglasi ye-C, inika i-FRP ukumelana neekhemikhali, ingakumbi ukumelana ne-asidi. Ukongeza, ngenxa yobuncinci bayo kunye nobubanzi befayibha obucolekileyo, inokufunxa i-resin engaphezulu ukuze yenze umaleko otyebileyo we-resin, igubungele ubume bezinto zokuqinisa ifayibha yeglasi (ezifana nokuluka okulukiweyo) kwaye zisebenza njengokugqitywa komphezulu.

4.I-Mat enenalitiIngahlulwahlulwa ngokwe-Chopped Fiber Needled Mat kunye ne-Continuous Filament Needled Mat.

- I-Mat eneenaliti zeFiber ezinqunqiweyolwenziwa ngokusika ifayibha yeglasi ibe bubude obuyi-50mm, ngokungenanjongo ibekwe kwi-substrate eyayibekwe ngaphambili kwibhanti yokuhambisa, ize emva koko ifakelwe iinaliti ezineencakuba. Iinaliti zityhala iifayibha ezinqunqiweyo kwi-substrate, kwaye ii-barb nazo zizisa ezinye iifayibha, zenze isakhiwo esinemilinganiselo emithathu. I-substrate esetyenziswayo inokuba ngelaphu elilukiweyo leglasi okanye ezinye iifayibha. Olu hlobo lwe-needled mat lune-texture efana ne-felt-like. Eyona misebenzi iphambili ibandakanya izixhobo zokufudumala kunye ne-acoustic insulation, izinto ze-lining, kunye nezinto zokucoca. Ingasetyenziswa nakwimveliso ye-FRP, kodwa i-FRP ephumayo inamandla aphantsi kunye nobubanzi bokusetyenziswa obulinganiselweyo.

- I-Filament eqhubekayo eneenaliti zeMatyenziwa ngokuphosa ngokungacwangciswanga iifilamenti zefayibha yeglasi eqhubekayo kwibhanti yemesh eqhubekayo kusetyenziswa isixhobo sokusasaza ifilamenti, kulandele ukuhlikihla ngebhodi yenaliti ukwenza imathi enesakhiwo sefayibha esidityanisiweyo esinobukhulu obuthathu. Le mathi isetyenziswa kakhulu ekuveliseni amaphepha e-thermoplastic aqinisiweyo e-fiber yeglasi.

5.I-Mat ethungiweyoIifayibha zeglasi ezinqunqiweyo ezisusela kwi-50mm ukuya kwi-60cm ubude zinokuthungwa kunye nomatshini wokuthunga ukwenza umata wefayibha onqunqiweyo okanye umata wefayibha omde. Owokuqala unokutshintsha i-CSM yesiqhelo ebotshelelwe kwi-binder kwezinye iinkqubo, kwaye owokugqibela unokutshintsha i-CFM ngandlela thile. Iingenelo zabo eziqhelekileyo kukungabikho kwezihlanganisi, ukuphepha ungcoliseko ngexesha lokuveliswa, ukusebenza kakuhle kwe-resin impregnation, kunye nexabiso eliphantsi.

Amalaphu eFayibha yeGlasi

Oku kulandelayo kwazisa ngeendidi ezahlukeneyo zamalaphu efayibha yeglasi elukiweyoimisonto yefayibha yeglasi.

1. Ilaphu leglasiIlaphu leglasi eliveliswa eTshayina lahlulwe kwiintlobo ze-alkali-free (E-glass) kunye ne-medium-alkali (C-glass); uninzi lwemveliso yangaphandle isebenzisa ilaphu leglasi elingena-alkali le-E-GLASS. Ilaphu leglasi lisetyenziswa kakhulu ukuvelisa ii-laminates ezahlukeneyo zombane ezikhuselayo, iibhodi zesekethe eziprintiweyo, imizimba yezithuthi, iitanki zokugcina, iinqanawa, ii-molds, njl. Ilaphu leglasi eliphakathi-alkali lisetyenziswa kakhulu ukuvelisa amalaphu okupakisha agqunywe ngeplastiki kunye nokusetyenziswa okuchasene nokugqwala. Iimpawu zelaphu zimiselwa ziimpawu zefayibha, uxinano lwe-warp kunye ne-weft, ulwakhiwo lweyarn, kunye nepatheni yoluko. Uxinano lwe-warp kunye ne-weft kunye nesakhiwo seyarn lumisela iipropati zomzimba zelaphu, ezinje ngobunzima, ubukhulu, kunye namandla okuqhekeka. Kukho iipateni ezintlanu ezisisiseko zoluko: ezicacileyo (ezifana noluko olujiweyo), i-twill (ngokubanzi ± 45°), i-satin (efana nelaphu elingacwangciswanga), i-leno (uluko oluphambili lwe-glass fiber mesh), kunye ne-matts (efana nelaphu le-oxford).

2.Iteyiphu yeFayibha yeGlasiYahlulwe yaba yiteyiphu enomphetho othungiweyo (umphetho we-selvage) kunye neteyiphu engathungiweyo (umphetho oqhekekileyo). Ipateni ephambili yokweluka ilula. Iteyiphu yefayibha yeglasi engena-alkali idla ngokusetyenziswa ukwenza izixhobo zombane ezifuna amandla aphezulu kunye neempawu ezilungileyo ze-dielectric.

3.Ilaphu leGlasi leFiber eliNye

- Ilaphu leWarp eliLungileyoyilaphu le-satin eliqhekekileyo elineentambo ezine okanye ilaphu le-satin elilukiweyo elineentambo ezirhabaxa kunye neentambo ezicolekileyo ze-weft. Uphawu lwayo kukuba namandla aphezulu ikakhulu kwicala le-warp (0°).

- KukwakhoIlaphu le-Glass Fiber Unidirectional Weft, ifumaneka kwiintlobo ezilukiweyo ezigobileyo nezilukiweyo. Ibonakala ngeentambo ezirhabaxa kunye neentambo ezigobileyo ezigobileyo, apho iintambo zefayibha yeglasi zijolise kakhulu kwicala lentambo, zinika amandla aphezulu kwicala lentambo (90°).

4.Ilaphu le-3D le-Glass Fiber (Ilaphu le-Stereoscopic)Amalaphu e-3D ahambelana namalaphu acwangcisiweyo. Iimpawu zawo zesakhiwo ziye zavela kwi-one-dimensional kunye ne-two-dimensional ukuya kwi-three-dimensional, nto leyo enika izixhobo ezihlanganisiweyo eziqiniswe yiyo ukuthembeka okuhle kunye nokuhambelana kwazo, nto leyo ephucula kakhulu amandla okucheba phakathi kwe-laminar kunye nokunyamezelana komonakalo kwee-composites. Zenzelwe ukuhlangabezana neemfuno ezikhethekileyo zeenqwelo-moya, zeenqwelo-moya, zezixhobo, kunye nezeelwandle, kwaye ukusetyenziswa kwazo ngoku kwandisiwe kwabandakanya iimoto, iimpahla zemidlalo, kunye nezixhobo zonyango. Kukho iindidi ezintlanu eziphambili: amalaphu e-3D alukiweyo, amalaphu e-3D alukiweyo, amalaphu e-3D angacwangciswanga kunye nalawo angacwangciswanga, amalaphu aluka nge-3D, kunye nezinye iintlobo zamalaphu e-3D. Imilo yamalaphu e-3D ibandakanya ibhloko, i-columnar, i-tubular, i-hollow truncated cone, kunye ne-variable-thickness irregular cross-sections.

5. Ilaphu le-Glass Fiber Preform (Ilaphu eliMile)Imilo yelaphu elingaphambi kokwakhiwa ifana kakhulu nemilo yemveliso ezenzelwe ukuyiqinisa, kwaye kufuneka zilukwe kwiimpahla ezilungiselelweyo. Ilaphu elinobume obufanayo liquka: iikepusi ezingqukuva, iikhowuni, iminqwazi, ilaphu elinobume obufana needumbbell, njl. Iimilo ezingalinganiyo ezifana neebhokisi kunye neehull zeenqanawa nazo zinokwenziwa.

6.Ilaphu leGlasi leFiber Core (Ilaphu lokuThunga elinobukhulu obungalinganiyo)Ilaphu elingundoqo lineeleya ezimbini ezihambelanayo zelaphu ezidityaniswe yimicu ethe nkqo emide. Imilo yalo enqamlezileyo inokuba ngunxantathu, uxande, okanye ubusi.

7.Ilaphu Elidityaniswe Nefayibha Yeglasi (I-Mat Ethungiweyo okanye I-Mat Elukiweyo)Yahlukile kwilaphu eliqhelekileyo kwaye ikwahluke kakhulu kwingqiqo eqhelekileyo ye-mat. Ilaphu elidityaniswe kakhulu lenziwa ngokugquma umaleko omnye wentambo ye-warp kunye nomaleko omnye wentambo ye-weft, uze uzithunge kunye ukuze zenze ilaphu. Iingenelo zelaphu ezidityaniswe ne-stitch ziquka:

- Inokunyusa amandla okuxinana, amandla okulwa nokwahlukana xa ixinezelekile, kunye namandla okugoba e-FRP laminates.

- Iyanciphisa ubunzimaIimveliso ze-FRP.

- Umphezulu othe tyaba wenza umphezulu we-FRP ube mpuluswa.

- Yenza kube lula ukusebenza kwezandla kwaye iphucule imveliso yabasebenzi. Le nto yokuqinisa ingathatha indawo ye-CFM kwi-FRP kunye ne-RTM edibeneyo, kwaye ingathatha indawo ye-roving elukiweyo kwimveliso yepayipi ye-FRP exutyiweyo.

Ixesha lokuthumela: Okthobha-22-2025