Kwiminyaka emibini edlulileyo, iqhutywa kukuguquka kwetekhnoloji kwezinto zokukhusela ezibaleka kubushushu kwiibhetri ezintsha zamandla, abathengi bafuna ngakumbi ukusebenza okuphuculweyo kokukhusela ubushushu kunye nokumelana nokutshaya okufana ne-ceramic—into ephambili yokumelana nefuthe lomlilo.

Umzekelo, ezinye izicelo zifuna amaqondo obushushu okucima ilangabi ngaphambili angama-1200°C ngelixa kugcinwa amaqondo obushushu angasemva angaphantsi kwama-300°C. Kwizinto zeenqwelo-moya, ukucima ilangabi ngaphambili kwe-acetylene kwi-3000°C kufuna amaqondo obushushu angasemva angaphantsi kwama-150°C. Eyona nto inzima kakhulu yimfuno ephezulu yokusebenza koxinzelelo kwi-silicone foam eyenziwe ngeseramikhi, efuna zombini iseti yoxinzelelo oluphantsi kunye nokugcinwa kobushushu obuhle kakhulu kubushushu kumaqondo obushushu aphezulu. Ezi zinto zidibene zibonelela ngeemfuno ezintsha zokukhusela ubushushu kwitekhnoloji yokukhusela ubushushu.

Iimfuno ezithile zokusebenza (zenzelwe ukubhekisela kuphela):

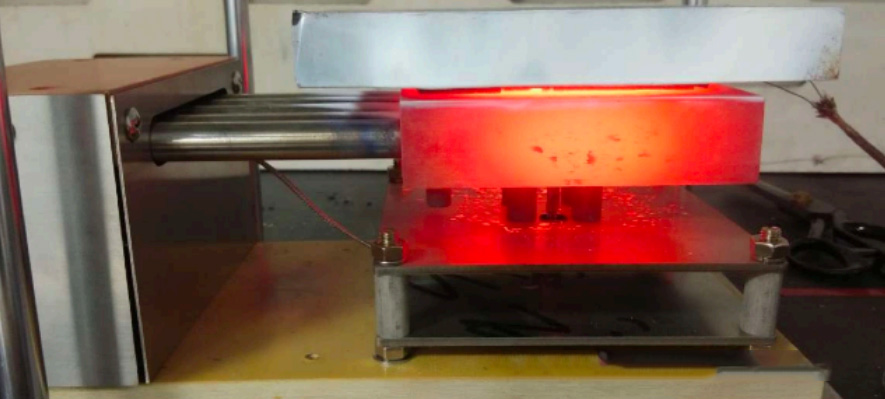

Fudumeza isampuli kwiqonga lokufudumeza njengoko kubonisiwe ngezantsi. Gcina umphezulu oshushu kwi-600 ± 25 °C imizuzu eli-10. Faka uxinzelelo lwe-0.8 ± 0.05 MPa kubushushu bovavanyo, uqinisekise ukuba ubushushu bomphezulu ongasemva buhlala bungaphantsi kwama-200 °C.

Namhlanje, sishwankathela la manqaku ukuze ubhekisele kuwo.

1. I-Synthetic Calcium Silicate – I-Thermal Insulation White Filler

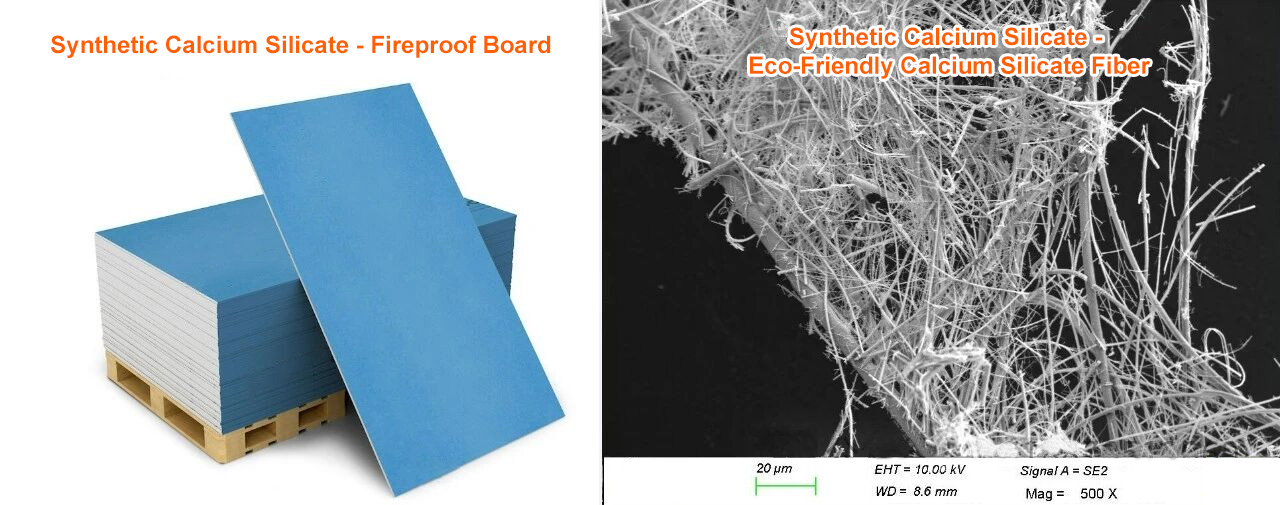

I-calcium silicate yokwenziwa ikhona ngeendlela ezimbini: izakhiwo ezinemingxuma/ezingqukuva kunye nezakhiwo ezinemicu efana ne-ceramic-fiber. Nangona kukho umahluko kwimilo kunye ne-morphological, zombini zisebenza njengezixhobo zokugcwalisa ezimhlophe ezikhusela ubushushu obuphezulu.

Ifayibha ye-calcium silicate eyenziweyo ilungele okusingqongileyo kwaye inobuhlobo nokusingqongileyoizixhobo zokukhusela ubushushu ezikhuselekileyoenokumelana nobushushu obuphezulu ukuya kuthi ga kwi-1200-1260°C. Umgubo wefayibha ye-calcium silicate eyenziwe ngokukodwa ecutshungulwe ngokukodwa ungasebenza njengesixhobo esiqinisiweyo sefayibha sokukhusela ubushushu obuphezulu.

I-calcium silicate eyenziweyo enemingxuma okanye engqukuva, okwangoku, inobumhlophe obuphezulu, kulula ukuyidibanisa, isakhiwo sayo esityebileyo se-nanoporous, ixabiso eliphezulu kakhulu lokufunxa ioyile (ukuya kuthi ga kwi-400 nangaphezulu), kunye nokukhululeka kwiibhola ze-slag okanye amasuntswana amakhulu. Ibonakalise ukusetyenziswa kwayo kwi-insulation ekwaziyo ukumelana nobushushu obuphezulu kunye neepaneli ezingatshiyo, ibonisa ukuba kunokwenzeka ukufakwa kwizixhobo ezikwaziyo ukumelana ne-ablation ezenziwe nge-ceramic ukubonelela nge-insulation ekwaziyo ukumelana nobushushu obuphezulu.

Ezinye izinto ezisetyenziswayo ziquka: izongezo zolwelo ezigudileyo, izinto zokugquma umgubo ezikhusela ubushushu obuphezulu, izinto zokuthwala iziqholo ezifunxayo, izinto ezithintela ukuvuza, izinto zokukhuhlana kwephedi yeebhuleki, irabha yesilicone enoxinzelelo oluphantsi kunye neoyile yesilicone ezizibolisayo, izizalisi zephepha, njl.njl.

2. I-Magnesium Aluminium Silicate eneMingxunya eneeLeyi- Ukufakwa kobushushu kunye nokumelana nobushushu obuphezulu

Le minerali ye-silicate ifuna i-calcination yobushushu obuphezulu kunye nokuchasana ukuya kuthi ga kwi-1200°C. Ngokuyintloko yenziwe nge-magnesium aluminium silicate, inesakhiwo esityebileyo esineembobo esinika amandla aphezulu okubopha, ukumelana kakuhle kwamanzi, ixesha elide lokuchasana, kunye nokusebenza kakuhle kweendleko.

Imisebenzi yayo ephambili ibandakanya ubushushu obuphezulu, ukunciphisa uxinano, ukuqina okuphuculweyo kokuchasana nobushushu, kunye nokumelana okuphuculweyo kokuchasana nobushushu kunye nobushushu bee-carbon layers kunye nee-casings. Usetyenziso luquka izixhobo zokuchasana ezenziwe nge-ceramic, iingubo ezisemgangathweni ezingatshiyo, izixhobo zokuchasana nokuchasana nobushushu, kunye nezixhobo zokuchasana nokuchasana nobushushu ezichasana nobushushu.

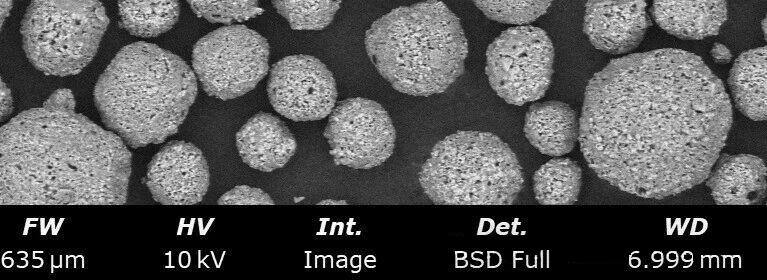

3. IiMicrospheres zeCeramic – Ukumelana nobushushu obuphezulu, Ukufakwa kobushushu, Amandla okucinezela

Ii-microspheres zeglasi ezingenamthungo ngokungathandabuzekiyo zizinto ezibalaseleyo zokukhusela ubushushu, kodwa ukumelana kwazo nobushushu akwanelanga. Amanqaku azo okuthambisa aqhele ukuba phakathi kwama-650-800°C, kunye namaqondo obushushu okunyibilika kwi-1200-1300°C. Oku kunciphisa ukusetyenziswa kwazo kwiimeko zokukhusela ubushushu obuphantsi. Phantsi kweemeko zobushushu obuphezulu ezifana ne-ceramicization kunye nokumelana ne-ablation, azisebenzi.

Iimicrospheres zethu ze-ceramic ezingenanto zisombulula le ngxaki. Ngokuyintloko zenziwe nge-aluminosilicate, zibonelela ngokumelana nobushushu obuphezulu, ubushushu obugqwesileyo, ukuchasana okuphezulu, kunye nokumelana nokuqhekeka okuphezulu. Izicelo ziquka izongezo ze-silicone ceramic, izixhobo zokuthintela ukuchasana, izongezo zobushushu obuphezulu zeeresini ze-organic, kunye nezongezo zerabha ezichasana nobushushu obuphezulu. Amacandelo aphambili aquka i-aerospace, uphando lolwandle olunzulu, izinto ezidityanisiweyo, iingubo, ukuthintela ukuchasana, ishishini le-petroleum, kunye nezixhobo zokuthintela ukuchasana.

Le yi-micropowder engqukuva engenanto ekwaziyo ukumelana nobushushu, kulula kakhulu ukuyifaka (ngokungafaniyo nee-microspheres zeglasi ezingenanto, ezifuna ukusasazeka okanye ukulungiswa kwangaphambili ukuze zongezwe ngokufanelekileyo) kwaye zinokumelana okuhle kakhulu nokuqhekeka. Uphawu lwayo oluphawulekayo kukuba yinto evulekileyo phezu kwamanzi engadadanga, nto leyo eyenza kube lula ukuyijiya nokuyihlalisa.

Ukongeza, ukukhankanywa okufutshane kweumgubo we-airgel—isixhobo sokufakelwa i-silica esineembobo ezenziweyo. I-Aerogel yaziwa ngokubanzi njengesixhobo sokukhusela ubushushu esibalaseleyo, esifumaneka kwiindidi ze-hydrophobic/hydrophilic. Oku kuvumela ukukhethwa kweendlela ezifanelekileyo zonyango ezisekelwe kwi-resin substrates, ukujongana nemingeni ye-aerogel powder yokusasazeka okulula kakhulu kunye nokuphucula ukusasazeka kwayo. Iipaste ze-aerogel ezisekelwe emanzini nazo ziyafumaneka ukuze zifakwe lula kwiinkqubo zamanzi.

Iimpawu ezikhethekileyo zokugquma ubushushu ezinemingxuma zepowder ye-airgel zivumela ukusetyenziswa kwayo kwezi zinto zilandelayo: – Iinqwelo zokongeza irabha kunye neplastiki – Izixhobo zokugquma ubushushu kwiibhetri ezintsha zamandla – Iingubo zokugquma ubushushu zokwakha – Iifayibha zelaphu zokugquma ubushushu – Iiphaneli zokugquma ubushushu zokwakha – Iingubo zokugquma ubushushu ezingatshiyo – Izincamathelisi zokugquma ubushushu.

Ixesha leposi: Sep-22-2025