Ukuzulazula ngqo kwi-CFRT

Ukuzulazula ngqo kwi-CFRT

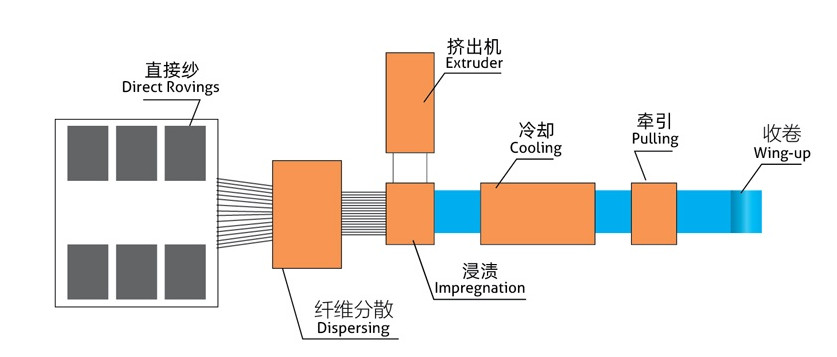

Ukujika ngqo kwi-Continuous Fiber Reinforced Thermoplastics kusetyenziswa kwinkqubo ye-CFRT. Iintambo ze-fiberglass zazisuswa ngaphandle kwi-bobbins eshelufini zaze zalungiswa kwicala elinye; Iintambo zazisasazwa kukuxinana kwaye zifudunyezwe ngumoya oshushu okanye i-IR; I-thermoplastic compound enyibilikisiweyo yabonelelwa yi-extruder yaza yafunxa i-fiberglass ngoxinzelelo; Emva kokupholisa, kwasekwa iphepha lokugqibela le-CFRT.

Iimbonakalo

● Akukho fuzz

● Ukuhambelana neenkqubo ezininzi ze-resin

● Ukucubungula kakuhle

● Ukusasazwa okugqwesileyo

● Iipropati ezintle kakhulu zoomatshini

Isicelo:

Isetyenziswa njengezithuthi, ulwakhiwo, uthutho kunye neenqwelo moya.

Uluhlu lweMveliso

| Into | Uxinano oluLula | Ukuhambelana kweResin | Iimbonakalo | Ukusetyenziswa kokugqibela |

| I-BHCFRT-01D | 300-2400 | I-PA, i-PBT, i-PET, i-TPU, i-ABS | Ukuhambelana neenkqubo ezininzi ze-resin, i-fuzz ephantsi | iimoto, ulwakhiwo, uthutho kunye neenqwelo moya |

| I-BHCFRT-02D | 400-2400 | I-PP, i-PE | Ukusasazwa okugqwesileyo, iipropati ezibalaseleyo zoomatshini | iimoto, ezokwakha, ezemidlalo, ezombane, neze-elektroniki |

| Ukuchongwa | ||||

| Uhlobo lweGlasi | E | |||

| Ukuzulazula ngqo | R | |||

| Ububanzi bentambo, μm | 400 | 600 | 1200 | 2400 |

| Uxinano oluLula, i-tex | 16 | 16 | 17 | 17 |

| Iiparameters zobugcisa | |||

| Uxinano oluLula (%) | Umxholo wobumanzi (%) | Ubungakanani bomxholo (%) | Amandla okuphuka (N/Tex) |

| I-ISO1889 | I-ISO3344 | I-ISO1887 | IS03341 |

| ±5 | ≤0.10 | 0.55±0.15 | ≥0.3 |

Inkqubo yeCFRT

Umxube onyibilikisiweyo we-polymer resin kunye nezongezo ufunyanwa nge-extruder. I-filament eqhubekayo ejikelezayo iyasasazeka kwaye ifunxwe ngokutsala umxube onyibilikisiweyo Emva kokupholisa, ukucola kunye nokujijeka. Izinto zokugqibela zenziwa