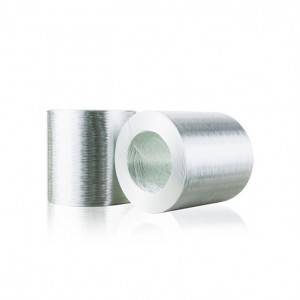

Ukuzulazula Ngokuthe Ngqo Kwi-Pultrusion

Ukuzulazula Ngokuthe Ngqo Kwi-Pultrusion

I-Direct Roving for Pultrusion iyahambelana ne-unsaturated polyester, i-vinyl ester, i-epoxy kunye ne-phenolic resins.

Iimbonakalo

●Inkqubo isebenza kakuhle kwaye ayisebenzi kakuhle

●Ukuhambelana neenkqubo ezininzi ze-resin

●Iimpawu ezilungileyo zoomatshini

● Imanzi ngokupheleleyo nangokukhawuleza

● Ukumelana nokugqwala kwe-asidi okugqwesileyo

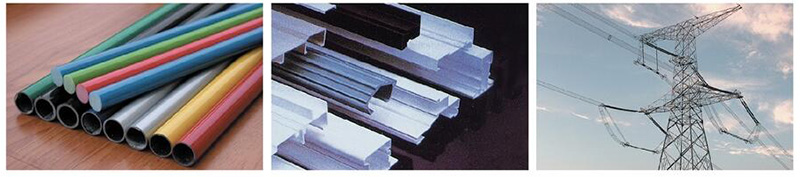

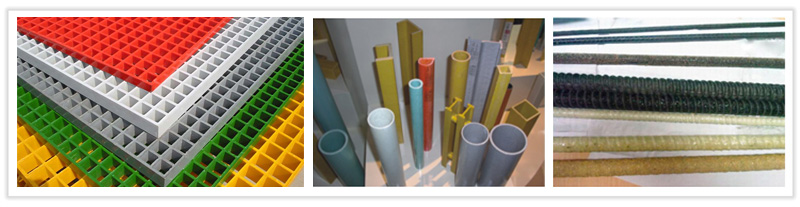

Isicelo:

Isetyenziswa kakhulu kwishishini lezakhiwo nokwakha, unxibelelwano kunye noshishino lwe-insulator.

Iiprofayili zePultrusion zezixhobo zemidlalo zangaphandle, iintambo ze-Optic, iibha ezahlukeneyo zecandelo, njl.

Uluhlu lweMveliso

| Into | Uxinano oluLula | Ukuhambelana kweResin | Iimbonakalo | Ukusetyenziswa kokugqibela |

| I-BHP-01D | 300,600,1200 | VE | Iyahambelana ne-matrix resin; Amandla aphezulu okuxinana kwemveliso yokugqibela edityanisiweyo | Isetyenziselwa ukwenza intambo ye-optic |

| I-BHP-02D | 300-9600 | UP,VE,EP | Iyahambelana ne-matrix resin; Iyamanzisa ngokukhawuleza; Iipropati ezintle kakhulu zoomatshini zemveliso edibeneyo | Isetyenziselwa ukwenza iibhari ezahlukeneyo zecandelo |

| I-BHP-03D | 1200-9600 | UP,VE,EP | Iyahambelana neeresini; Iipropati ezibalaseleyo zoomatshini zemveliso edityanisiweyo | Isetyenziselwa ukwenza iibhari ezahlukeneyo zecandelo |

| I-BHP-04D | 1200,2400 | EP, iPolyester | Intambo ethambileyo; Ifuzz ephantsi; Iyahambelana neeresini | Ifanelekile ekwenziweni kwegridi ebunjiweyo |

| I-BHP-05D | 2400-9600 | UP,VE,EP | Iipropati ezibalaseleyo zokuxinana, ukugoba kunye nokucheba iimveliso ze-composites | Iiprofayili ezingasebenzi kakuhle |

| I-BHP-06D | 2400,4800,9600 | EP | Amandla aphezulu efayibha, Ukuthembeka okuhle kunye neribhoni, Ukuhambelana ne-epoxy resin, I-resin imanzi ngokupheleleyo kwaye ikhawuleza, Iipropati ezilungileyo zoomatshini, Iipropati ezilungileyo zombane ezigqityiweyo | iintonga zokwambathisa kunye nee-stanchions zokwambathisa |

| Ukuchongwa | |||||||

| Uhlobo lweGlasi | E | ||||||

| Ukuzulazula ngqo | R | ||||||

| Ububanzi bentambo, μm | 13 | 16 | 17 | 17 | 22 | 24 | 31 |

| Uxinano oluLula, i-tex | 300 | 200 400 | 600 735 | 1100 1200 | 2200 | 2400 4800 | 9600 |

| Iiparameters zobugcisa | |||

| Uxinano oluLula (%) | Umxholo wobumanzi (%) | Ubungakanani bomxholo (%) | Amandla okuphuka (N/Tex) |

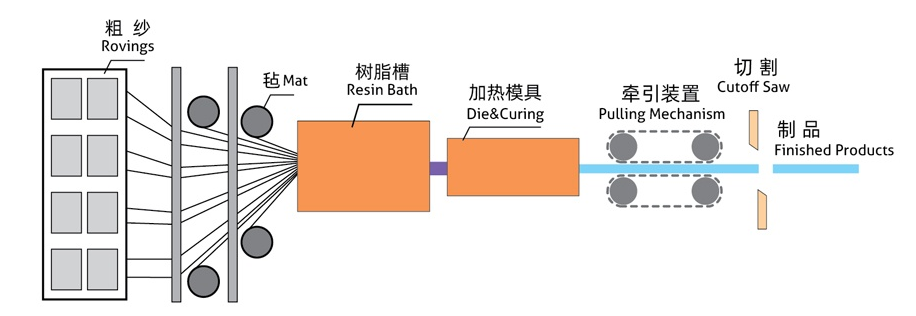

Inkqubo yokuphambuka

Iirovings, iimathi okanye ezinye ilaphu zitsalwa ngebhafu yokufunxa i-resin zize zifakwe kwi-diye eshushu kusetyenziswa isixhobo sokutsala esiqhubekayo. Iimveliso zokugqibela zenziwa phantsi kobushushu obuphezulu kunye neemeko zoxinzelelo oluphezulu.