Ukongeza iiglasi ezingenanto kwiimveliso zerabha kunokuzisa iingenelo ezininzi:

1, Ukunciphisa Ubunzima

Iimveliso zerabha nazo zijolise kwicala elikhaphukhaphu nelihlala ixesha elide, ingakumbi ukusetyenziswa okuvuthiweyo kweziseko zerabha ze-microbeads, ukusuka kuxinano oluqhelekileyo lwe-1.15g/cm³ okanye ngaphezulu, yongeza iindawo ezi-5-8 ze-microbeads, ezincitshiswe ukuya kwi-1.0g/cm³ (eyaziwa ngokuba "yi-floating phezu kwamanzi"), kukho inqanaba elithile lokukwazi kwe-R & D kwabathengi ngokongeza ii-microbeads kuya kuba noxinano lwe-0.9 okanye i-0.85g/cm³, okunciphisa kakhulu uxinano ngerabha, izihlangu kunye nemeko efanayo ngaphambi kokunciphisa ubunzima be-20% okanye ngaphezulu. Okwangoku, abanye abathengi abanobuchule obuthile be-R & D baya kwenza uxinano lube yi-0.9 okanye i-0.85g/cm³ ngokongeza ii-microbeads, nto leyo enciphisa kakhulu uxinano ngerabha, kwaye ubunzima bezihlangu buya kuncitshiswa malunga ne-20% phantsi kwemeko efanayo nangaphambili.

2, Ubushushu bokugquma

Ulwakhiwo olungenanto lwee-beads zeglasi ezingenanto lunika ii-beads ubushushu obuphantsi, njengoko isizali sobushushu obuphantsi esongezwa kwizinto zerabha sinokudlala isiphumo esihle kakhulu sobushushu, njengakwii-thermal insulation pads, ii-thermal insulation boards kunye nezinye iimveliso ezisetyenzisiweyo.

3, Ukufunxwa kwesandi kunye nokunciphisa ingxolo

Ngaphakathi kweentsimbi zeglasi ezingenanto kukho igesi ebhityileyo, amaza esandi kule ndawo aya kuba buthathaka, ngomlinganiselo othile wokongeza ukudlala isiphumo esihle kakhulu sokufunxwa kwesandi kunye nokunciphisa ingxolo.

4, uzinzo oluhle olunemilinganiselo

Izinto ezisisiseko zeentsimbi yiglasi ene-coefficient ephantsi yokwandiswa kobushushu, uzinzo oluhle xa luphantsi koxinzelelo lobushushu, xa lufakwe kwizinto zerabha luya kunika imveliso uzinzo olungcono lobukhulu.

Iingcebiso zokusetyenziswa ekucutshungulweni:

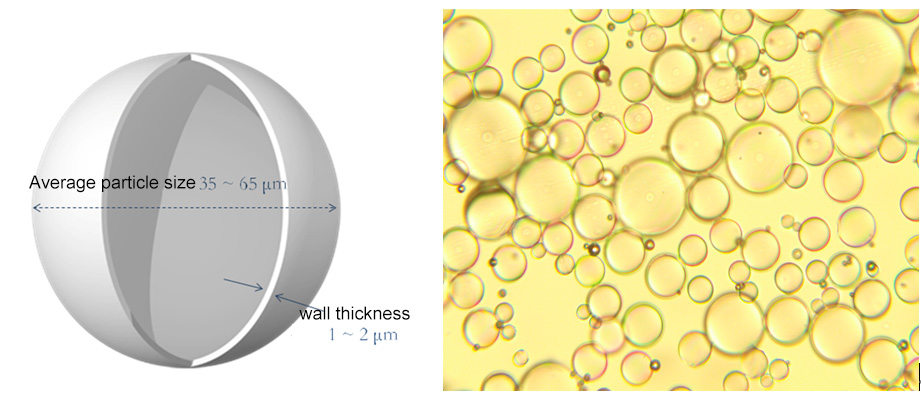

1, izixhobo zokwenza iimveliso zerabha ngokubanzi zixineneyo, zivula, zikhuphela isikrufu esinye, njl., kuba iintsimbi zisetyenziswa kwiglasi, udonga lulolwamasuntswana aqinileyo, kwaye amandla okucheba oomatshini aya kwaphulwa ngokuyinxenye, iintsimbi ziya kulahlekelwa ngumsebenzi wazo owahlukileyo emva kokuba zaphukile.

2, iiglasi ezingenanto zinemodeli ezahlukeneyo kunye neeparameters ezihambelanayo, ngokwezixhobo ezahlukeneyo kunye neemfuno zemveliso ukukhetha iimveliso zeentsimbi ezifanelekileyo kubaluleke kakhulu, iSt. Leite icebisa ukusetyenziswa kweHL38, HL42, HL50, HS38, HS42 kwiimveliso zerabha.

3, xa isetyenziswa kumatshini wokucoca, kukho i-rotor kwi-shear yezinto zerabha, ii-beads azinakuphetshwa ngamandla okucoca, ukuze kangangoko kunokwenzeka ukunciphisa ixesha lee-beads ekucoceni, kucetyiswa ukuba kongezwe ekucoceni okusemva kwexesha ukuqinisekisa ukuba ii-beads ezongeziweyo ekucoceni imizuzu emi-3-5 zinokusasazwa ngokulinganayo; kumatshini wokucoca, isithuba se-roller kunye nexesha lokucoca lokutyunyuzwa kwee-beads zinempembelelo enkulu, kucetyiswa ukuba isithuba se-roller singaphezulu kwe-2mm, ixesha lokucoca akufuneki libe lide kakhulu; Amandla okucoca ngokubanzi e-single screw extruder mancinci, xa sithetha, impembelelo kwi-microbeads incinci, kucetyiswa ukuba kunyuswe ubushushu be-extrusion nge-5 ℃, kuncitshiswe i-viscosity yezinto eziluncedo ngakumbi ekubumbeni i-extrusion, kuncitshiswe ii-microbeads eziphukileyo.

Ixesha lokuthumela: Julayi-21-2023