I-Basalt Fiber

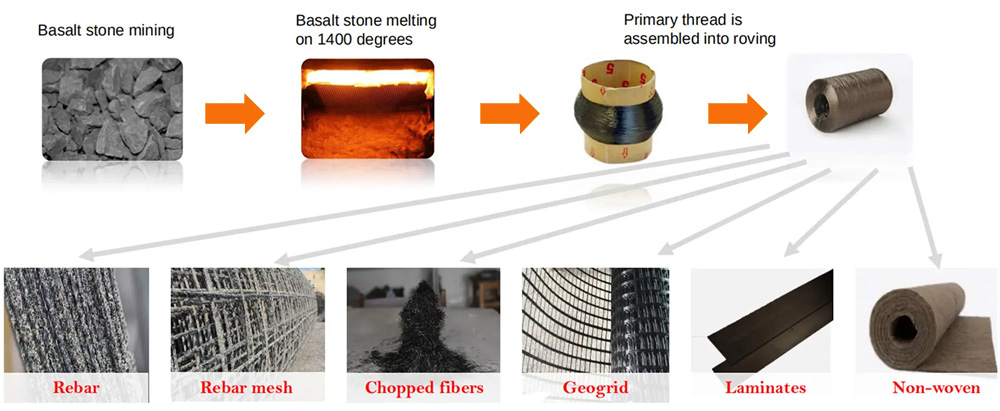

Ifayibha yeBasalt yifayibha eqhubekayo ethathwe kwi-basalt yendalo. Yilitye le-basalt kwi-1450 ℃ ~ 1500 ℃ emva kokunyibilika, ngokusebenzisa ipleyiti yokutsala nge-platinum-rhodium alloy wire drawing leaking speed-drawing eyenziwe ngefayibha eqhubekayo. Umbala wefayibha ye-basalt yendalo ecocekileyo ngokubanzi imdaka. Ifayibha yeBasalt luhlobo olutsha lwezinto zefayibha eziluhlaza ezisebenza kakuhle nezingaphiliyo, ezenziwe nge-silica, i-alumina, i-calcium oxide, i-magnesium oxide, i-iron oxide kunye ne-titanium dioxide kunye nezinye ii-oxide.Ifayibha eqhubekayo yeBasaltAyinamandla aphezulu nje kuphela, kodwa ikwanazo neempawu ezahlukeneyo ezintle ezifana nokufakelwa kombane, ukumelana nokugqwala, ukumelana nobushushu obuphezulu njl. Ukongeza, inkqubo yokuvelisa i-basalt fiber igqibe ekubeni ivelise inkunkuma encinci, ungcoliseko oluncinci kwindalo esingqongileyo, kwaye imveliso inokonakala ngokuthe ngqo kwindalo esingqongileyo emva kwenkunkuma, ngaphandle komonakalo, ngoko ke zizinto eziluhlaza ngokwenene, ezinobuhlobo nokusingqongileyo. Iifayibha eziqhubekayo zeBasalt zisetyenziswe kakhulu kwii-composites eziqiniswe yifayibha, izixhobo zokungqubana, izixhobo zokwakha iinqanawa, izixhobo zokukhusela ubushushu, ishishini leemoto, amalaphu okucoca obushushu obuphezulu, kunye namasimi okukhusela.

Iimpawu

① Izinto ezisetyenziswayo ezaneleyo

Ifayibha yeBasaltyenziwe nge-basalt ore enyibilikisiweyo netsaliweyo, kwaye i-basalt ore eMhlabeni naseNyangeni zizinto ezigciniweyo ezingakhethi cala, ngenxa yeendleko zezinto ezikrwada ziphantsi kakhulu.

② Izinto ezinobuhlobo nokusingqongileyo

I-Basalt ore yinto yendalo, akukho boron okanye ezinye ii-alkali metal oxides ezikhutshwayo ngexesha lenkqubo yemveliso, ngoko ke akukho zinto zinobungozi ezifumaneka kumsi, umoya awuyi kubangela ungcoliseko. Ngaphezu koko, imveliso ihlala ixesha elide, ngoko ke luhlobo olutsha lwezinto eziluhlaza ezisebenzayo zokukhusela okusingqongileyo ezinexabiso eliphantsi, ukusebenza okuphezulu kunye nococeko olufanelekileyo.

③ Ubushushu obuphezulu kunye nokumelana namanzi

Ubushushu bokusebenza kwefayibha ye-basalt eqhubekayo ngokubanzi yi-269 ~ 700 ℃ (indawo yokuthambisa ye-960 ℃), ngelixa ifayibha yeglasi ye-60 ~ 450 ℃, ubushushu obuphezulu befayibha ye-carbon bunokufikelela kwi-500 ℃ kuphela. Ngokukodwa, ifayibha ye-basalt kwi-600 ℃ isebenza, amandla ayo emva kokuqhekeka asenokugcina i-80% yamandla okuqala; ukusebenza kwi-860 ℃ ngaphandle kokuncitshiswa, nokuba ukumelana nobushushu koboya bezimbiwa obuhle ngeli xesha emva kokuqhekeka kunokugcinwa kwi-50% -60% kuphela, uboya beglasi buyatshatyalaliswa ngokupheleleyo. Ifayibha ye-carbon malunga ne-300 ℃ kwimveliso ye-CO kunye ne-CO2. Ifayibha ye-basalt kwi-70 ℃ phantsi kwesenzo samanzi ashushu inokugcina amandla aphezulu, ifayibha ye-basalt kwiiyure ezili-1200 inokulahlekelwa yinxalenye yamandla.

④ Uzinzo oluhle lweekhemikhali kunye nokumelana nokugqwala

I-fiber ye-basalt eqhubekayo iqulethe i-K2O, i-MgO) kunye ne-TiO2 kunye nezinye izinto, kwaye ezi zinto zokuphucula ukumelana nokugqwala kweekhemikhali zefayibha kunye nokusebenza okungangeni manzi ziluncedo kakhulu, zidlala indima ebaluleke kakhulu. Zinenzuzo ngakumbi xa zithelekiswa nokuzinza kweekhemikhali zefayibha zeglasi, ingakumbi kwi-alkaline kunye ne-acidic media. Iifayibha ze-basalt ezicacileyo ngakumbi kwisisombululo se-Ca (OH) 2 esigcweleyo kunye nesamente kunye nezinye izinto ze-alkaline media nazo zinokugcina ukumelana okuphezulu nokusebenza kokugqwala kwe-alkaline.

⑤ Imodulus ephezulu yokuthamba kunye namandla okuxinana

Imodulus yokuthamba kwefayibha ye-basalt yi-9100 kg/mm-11000 kg/mm, ephezulu kunefayibha yeglasi engena-alkali, i-asbestos, ifayibha ye-aramid, ifayibha ye-polypropylene kunye nefayibha ye-silica. Amandla okutsalwa kwefayibha ye-basalt yi-3800–4800 MPa, ephezulu kunefayibha enkulu ye-tow carbon, ifayibha ye-aramid, ifayibha ye-PBI, ifayibha yentsimbi, ifayibha ye-boron, ifayibha ye-alumina, kwaye iyafana nefayibha yeglasi ye-S. Ifayibha ye-basalt inobunzima obuyi-2.65-3.00 g/cm3 kunye nobunzima obuphezulu obuyi-5-9 degrees kwisikali sobunzima be-Mohs, ngoko ke inokumelana okuhle kokurhawuzelelwa kunye neempawu zokuqinisa ukutsalwa. Amandla ayo oomatshini adlula kakhulu lawo efayibha yendalo kunye neefayibha zokwenziwa, ngoko ke sisixhobo sokuqinisa esifanelekileyo, kwaye iimpawu zayo zoomatshini ezilungileyo ziphambili kwiifayibha ezine eziphambili zokusebenza okuphezulu.

⑥ Ukusebenza kakuhle kokukhusela isandi

I-fiber ye-basalt eqhubekayo inomgangatho ophezulu wokuthintela isandi, ukusebenza kokufunxa isandi, ukusuka kwi-fiber kwi-coefficient eyahlukeneyo yokufunxa isandi kunokufundwa, ngokwanda kwamaza, i-coefficient yayo yokufunxa isandi iyanda kakhulu. Njengokukhethwa kwe-fiber ye-basalt ye-1-3μm ububanzi eyenziwe ngezinto ezifunxa isandi (ubuninzi be-15 kg/m3, ubukhulu be-30mm), kwi-audio yeemeko ze-100-300 Hz, 400-900 Hz kunye ne-1200-7,000 HZ, i-coefficient yokufunxa isandi se-0.05~0.15, 0.22~0.75 kunye ne-0.85~0.93, ngokulandelanayo.

⑦ Iimpawu ezibalaseleyo ze-dielectric

Ukumelana nomthamo we-fiber ye-basalt eqhubekayo kungaphezulu kakhulu kunokoIfayibha yeglasi ye-E, eneempawu ezintle kakhulu ze-dielectric. Nangona i-basalt ore iqulethe iqhekeza elimalunga ne-0.2 yee-oxides eziqhubayo, kodwa ukusetyenziswa kwearhente ekhethekileyo yokungena ngaphakathi kunyango olukhethekileyo lomphezulu, i-angle ye-dielectric yokusetyenziswa kwe-basalt fiber kune-fiber yeglasi iphantsi ngama-50%, i-volume resistivity yefayibha ikwaphezulu kune-fiber yeglasi.

⑧ Ukuhambelana kwendalo kwe-silicate

Ukusasazwa kakuhle ngesamente kunye nekhonkrithi, ukubopha okuqinileyo, umlinganiselo ohambelanayo wokwanda kunye nokucutheka kobushushu, ukumelana okuhle kwemozulu.

⑨ Ukufunxwa komswakama okuphantsi

Ukufunxwa komswakama kwi-basalt fiber kungaphantsi kwe-0.1%, kungaphantsi kune-aramid fiber, i-rock wool kunye ne-asbestos.

⑩ Ukuqhuba kobushushu obuphantsi

Ukuqhuba kobushushu be-basalt fiber yi-0.031 W/mK – 0.038 W/mK, engaphantsi kune-aramid fiber, i-alumino-silicate fiber, i-alkali-free glass fiber, i-rockwool, i-silicon fiber, i-carbon fiber kunye ne-stainless steel.

Iglasi yefayibha

I-Fiberglass, into engeyoyasemethini engaphiliyo enomsebenzi ogqwesileyo, ineenzuzo ezahlukeneyo ezifana nokugcina ubushushu obufanelekileyo, ukumelana nobushushu, ukumelana nokugqwala okuhle, amandla aphezulu oomatshini, kodwa ingxaki kukungakwazi ukukrala nokukrwela kakuhle. Isekelwe kwi-chlorite, isanti ye-quartz, ilitye lekalika, i-dolomite, ilitye le-calcium le-boron, ilitye le-magnesium le-boron, iintlobo ezintandathu ze-ores njengezinto eziluhlaza ngokunyibilika ngobushushu obuphezulu, ukutsalwa, ukujijwa, ukuluka kunye nezinye iinkqubo ekwenziweni kobubanzi be-monofilament yayo kwii-microns ezimbalwa ukuya kwii-microns ezingaphezu kwama-20, okulingana neenwele ze-1/20-1/5, inqwaba nganye ye-fiber filaments ngamakhulu okanye amawaka e-monofilament composition.Iglasi yefayibhaidla ngokusetyenziswa njengezinto zokuqinisa izinto ezidityanisiweyo, izinto zokukhusela umbane kunye nezinto zokukhusela ubushushu, iibhodi zesekethe kunye nezinye iindawo zoqoqosho lwesizwe.

Iipropati zezinto ezibonakalayo

Iqondo lokunyibilika: iglasi luhlobo lweqondo lokunyibilika elingacwangciswanga, elingenalo iqondo lokunyibilika elizinzileyo, ngokubanzi kukholelwa ukuba iqondo lokuthambisa liyi-500 ~ 750 ℃.

Iqondo lokubila: malunga ne-1000 ℃

Ubuninzi: 2.4~2.76 g/cm3

Xa ifayibha yeglasi isetyenziswa njengezinto zokuqinisa iiplastiki eziqinisiweyo, uphawu olukhulu ngamandla ayo aphezulu okuxinana. Amandla okuxinana kwisimo esiqhelekileyo yi-6.3 ~ 6.9 g / d, imeko emanzi yi-5.4 ~ 5.8 g / d. Ukumelana nobushushu kulungile, amaqondo obushushu afikelela kwi-300 ℃ ngamandla angasebenziyo. Ine-insulation yombane egqwesileyo, sisixhobo sokukhusela umbane esikumgangatho ophezulu, sikwasetyenziselwa izinto zokukhusela ubushushu kunye nezinto zokukhusela umlilo. Ngokubanzi idlakazwa kuphela yi-alkali eqinisiweyo, i-hydrofluoric acid kunye ne-phosphoric acid eqinisiweyo.

Iimpawu eziphambili

(1) Amandla aphezulu okuxinana, ubude obuncinci (3%).

(2) Ukuqina okuphezulu kokuqina, ukuqina okuhle.

(3) Ukwandiswa ngaphakathi kwemida yokuthamba kunye namandla aphezulu okutsalwa, ngoko ke ifunxa amandla amakhulu okubetha.

(4) Ifayibha engeyoyamvelo, ayitshi, inokumelana kakuhle neekhemikhali.

(5) Ukufunxwa kwamanzi kancinci.

(6) Uzinzo oluhle lwesikali kunye nokumelana nobushushu.

(7) Ukusebenziseka kakuhle, kungenziwaimicu, iinyanda, iifelt, amalaphukunye nezinye iintlobo ezahlukeneyo zeemveliso.

(8) Ingadlulisi nto kwaye ilula ukuyihambisa.

(9) Ukunamathela kakuhle kwi-resin.

(10) Ayibizi kakhulu.

(11) Akulula ukuyitshisa, ingaxutywa kwiibhile ezingathi yiglasi xa kushushu kakhulu.

Ixesha leposi: Epreli-11-2024