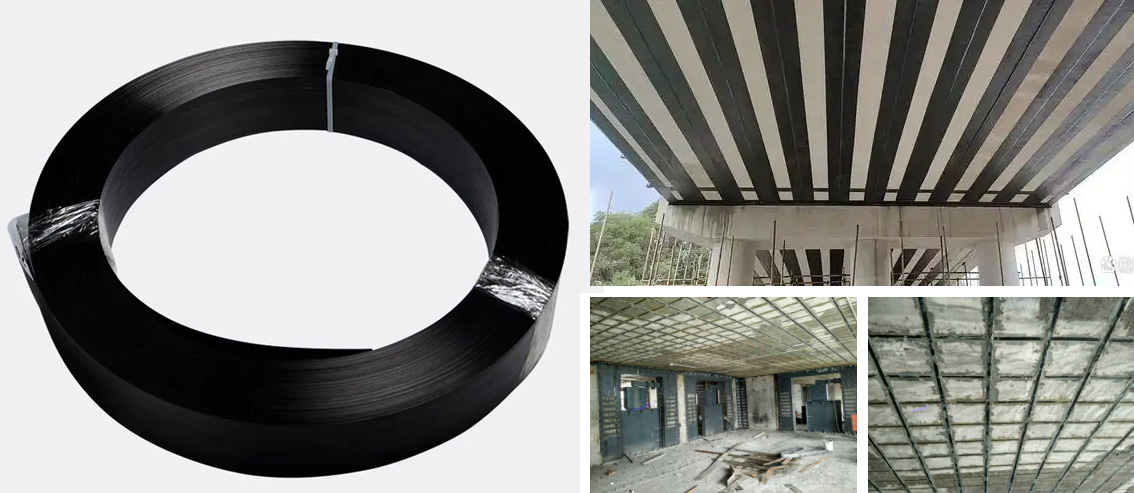

Iimpawu zeMveliso

Amandla aphezulu kunye nokusebenza kakuhle, ukumelana nokugqwala, ukumelana nomothuko, ukumelana neempembelelo, ulwakhiwo olulula, ukuqina okuhle, njl.

Ububanzi besicelo

Ukugoba imiqadi yekhonkrithi, ukuqinisa ukucheba, iislabhu zomgangatho zekhonkrithi, ukuqinisa idekhi yebhulorho, ikhonkrithi, iindonga zokwakha ngezitena, ukuqinisa iindonga zesikere, iitonela, amachibi okubhukuda kunye nokunye ukuqinisa ukuqinisa.

Ukugcina kunye nokuthuthwa

Ifanele igcinwe kwindawo eyomileyo, epholileyo nengena umoya, iphephe imvula okanye ilanga.

Inkqubo yokuthutha kunye nokugcina ayizukuba phantsi koxinzelelo, ukuze kuthintelwe ukonakalaifayibha yekhabhoni.

Imiyalelo yokwakha yokuqinisa ipleyiti yeVibranium

1. Unyango lwe-substrate yekhonkrithi

(1) Fumana uze ubeke umgca ngokwemizobo yoyilo kwindawo yokuncamathisela eyilelweyo.

(2) Umphezulu wekhonkrithi kufuneka ususwe kumaleko omhlophe, ioyile, uthuli, njl.njl., uze usebenzise i-engile grinder ukuze ucofe umaleko womphezulu onobukhulu obuyi-1 ~ 2mm uze uwucoce nge-blower ukuze utyhile umphezulu ococekileyo, othe tyaba, noqinileyo ngokwesakhiwo, ukuba kukho iintanda kwikhonkrithi eqinisiweyo, kufuneka kuqala kuxhomekeke kubukhulu beentanda ukuze ukhethe ukuzalisa iglu okanye i-grouting glue grouting uze emva koko uqinise.

2, unyango lokulinganisa

Ukuba kukho iziphene, imingxunya kunye nesinqe esiphezulu kwiindawo ezidityanisiweyo zetemplate kumphezulu oncamathiselweyo, sebenzisa iglu yokuleyisha ukuze ukrwele uze ugcwalise ukulungiswa ukuqinisekisa ukuba akukho mahluko ucacileyo wokuphakama kwiindawo ezidityanisiweyo, iziphene kunye nemingxunya igudile kwaye igudile. Ukuleyisha iglu uze uncamathisele ibhodi yefayibha yekhabhoni.

3. Ncamathiselaibhodi yefayibha yekhabhoni

(1) Sika ibhodi yefayibha yekhabhoni ngokobungakanani obufunekayo kuyilo.

(2) I-A component yesakhiwo kunye ne-B component ngokwe-ratio ye-2:1 configuration, ukusetyenziswa kwe-mixer mixer, ixesha lokuxuba malunga nemizuzu emi-2 ~ 3, ukuxuba ngokulinganayo, kunye nokuthintela ukungcola kothuli okuxutyiweyo. I-Activation glue edibeneyo ngexesha elinye akufuneki ibe ninzi kakhulu, ukuqinisekisa ukuba i-configuration ye-finished igqityiwe ngaphakathi kwemizuzu engama-30 (25 ℃).

(3) Umphezulu webhodi yefayibha yekhabhoni kufuneka ucinywe, kusetyenziswa iplastiki yokukrala iza kugqunywa ngeglu yolwakhiwo kwibhodi yefayibha yekhabhoni, ubukhulu beglu yolwakhiwo bube yi-1-3mm (indawo ephakathi yebhodi yefayibha yekhabhoni yi-3mm), yayiphakathi kwamacala atyebileyo obunzima obuncinci, obuphakathi buyi-2mm.

(4) Beka ibhodi yefayibha yekhabhoni kwisiseko sokuqinisa ikhonkrithi, ngerola yerabha efaka uxinzelelo olwaneleyo, ukuze i-adhesive yolwakhiwo evela kumacala omabini okuphuphuma, ukuqinisekisa ukuba akukho mngxuma, ukuqinisekisa ukuba ibhodi yefayibha yekhabhoni kunye nesiseko sekhonkrithi zinobukhulu obuyi-2mm ngokuthe ngqo be-adhesive.

(5) Susa izinto ezincamathelayo ezingaphaya komda, sebenzisa ibha yomthi okanye isakhelo sentsimbi ukuxhasa nokulungisa ibhodi yefayibha yekhabhoni, faka uxinzelelo ngokufanelekileyo, kwaye ususe inkxaso emva kokuba i-adhesive yolwakhiwo ilungisiwe. Xa iibhodi ezininzi zefayibha yekhabhoni zincamatheliswe ngaxeshanye, umsantsa phakathi kweebhodi ezimbini awukho ngaphantsi kwe-5mm.

(6) ncamathisela iileya ezimbini zebhodi yefayibha yekhabhoni kufuneka zibe yintlama eqhubekayo, umaleko ongezantsi webhodi yefayibha yekhabhoni kumacala omabini kufuneka ucinywe, njengoko ungenakuncamathiselwa ngoko nangoko uze uvule intlama ngaphambi kokuba umaleko ongezantsi webhodi yefayibha yekhabhoni uphinde wenze umsebenzi wokucoca. Ukuba izixhobo zokuqinisa kufuneka zenze ukhuseleko lwe-coating, ungayibrasha i-coating yomaleko okhuselayo emva kokulungisa i-resin.

Amanyathelo okukhusela ulwakhiwo

1. Xa ubushushu bungaphantsi kwe-5℃, umswakama ohambelanayo RH>85%, umxholo wamanzi womphezulu wekhonkrithi ungaphezulu kwe-4%, kwaye kukho ithuba lokuba kubekho ukufuma, ulwakhiwo aluyi kwenziwa ngaphandle kwamanyathelo asebenzayo. Ukuba iimeko zokwakha azinakufikelelwa, kuyimfuneko ukusebenzisa indlela yokufudumeza umphezulu osebenzayo ukuze kufezekiswe ubushushu obufunekayo, umswakama kunye nomxholo womswakama kunye nezinye iimeko ngaphambi kokwakhiwa, ubushushu bokwakha obuyi-5℃ -35℃ bufanelekile.

2. Ngenxa yokuba i-carbon fiber ingumhambisi wombane olungileyo, kufuneka igcinwe kude nombane.

3. I-resin yokwakha kufuneka igcinwe kude nomlilo ovulekileyo kunye nelanga elithe ngqo, kwaye i-resin engasetyenziswanga kufuneka ivalwe.

4. Abasebenzi bokwakha nabahlolayo kufuneka banxibe iimpahla zokuzikhusela, izigcina-ntloko zokhuseleko, iimaski, iiglavu, neeglasi zokuzikhusela.

5. Xa i-resin inamathela eluswini, kufuneka ihlanjwe ngesepha namanzi ngoko nangoko, itshizwe emehlweni ngamanzi kwaye inikwe unyango ngexesha elifanelekileyo. 6, ulwakhiwo ngalunye lugqityiwe, ulondolozo lwendalo zingadlulanga iiyure ezingama-24 ukuqinisekisa ukuba akukho mpembelelo yangaphandle kunye nezinye iziphazamiso.

7. Inkqubo nganye yenkqubo, kwaye emva kokugqitywa kwayo, kufuneka ithathe amanyathelo afanelekileyo ukuqinisekisa ukuba akukho ngcoliseko okanye ukungena kwamanzi emvula. 8. Ulwakhiwo lwendawo yokwakha yeglue yolwakhiwo kufuneka igcinwe inomoya ococekileyo.

9. ngenxa yokusongwa kweibhodi yefayibha yekhabhoniinoxinzelelo olukhulu, xa kukhutshwa ibhodi yefayibha yekhabhoni kufuneka abantu abayi-2-3 xa kukhutshwa ibhodi, ukuthintela ukuba ibhodi yefayibha yekhabhoni iphume yenzekele.

10. Inkqubo yokuphatha ipleyiti yekhabhoni kufuneka ibe lula, ingavumelekanga kwizinto eziqinileyo kwaye umntu ayinyathele.

11. Ulwakhiwo luhlangabezane nokwehla ngequbuliso kobushushu, i-viscosity ye-adhesive yolwakhiwo iya kubonakala inkulu, ungathatha amanyathelo okufudumeza, njengezibane ze-tungsten iodine, ii-oven zombane okanye iibhafu zamanzi kunye nezinye iindlela zokunyusa ubushushu be-glue ngaphambi kokuba uyisebenzise ukuze uyifudumeze ukuya kuma-20 ℃ -40 ℃.

Ixesha leposi: Epreli-27-2025