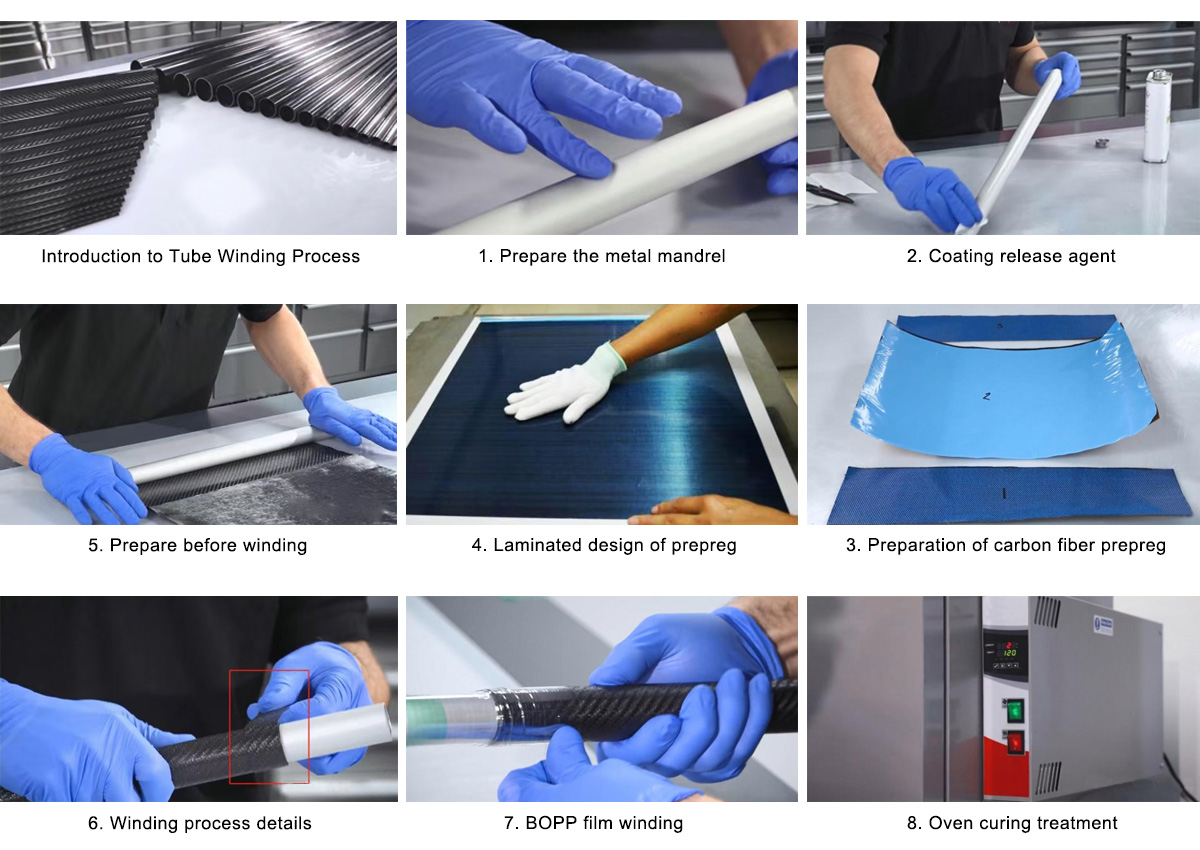

1. Intshayelelo kwiNkqubo yokuQokelela iityhubhu

Ngale sifundo, uza kufunda indlela yokusebenzisa inkqubo yokujika ityhubhu ukwenza izakhiwo zetyhubhu usebenzisa ii-carbon fiber prepregs kumatshini wokujika ityhubhu, ngaloo ndlela uvelise amandla aphezulu.iityhubhu zefayibha yekhabhoniLe nkqubo isetyenziswa kakhulu ngabavelisi bezinto ezidityanisiweyo.

Ukuba unqwenela ukuvelisa iityhubhu ezinamacala afanayo okanye i-taper eqhubekayo, inkqubo yokujika iityhubhu yeyona ndlela ifanelekileyo. Konke okudingayo yi-mandrel yesinyithi enobukhulu obufanelekileyo kunye ne-oven yokwenza iityhubhu zefayibha yekhabhoni ezenzelwe wena ngokweemfuno zakho ezithile.

Kwiityhubhu zefayibha yekhabhoni ezimile okweemilo ezintsonkothileyo, ezifana neehandlebars okanye izakhiwo zesakhelo setyhubhu ezintsonkothileyo ezifana neefolokhwe zokumiswa okanye iifreyimu zebhayisekile, iteknoloji ye-split-mold yeyona ndlela ikhethwayo. Ngoku siza kubonisa indlela yokusebenzisa iteknoloji ye-split-mold ukuvelisa ezi tyhubhu zefayibha yekhabhoni ezintsonkothileyo.

2. Ukucutshungulwa kunye nokulungiswa kweeMandrel zesinyithi

- Ukubaluleka kweeMandrel zeMetal

Ngaphambi kokuba uqale inkqubo yokusonga ityhubhu, inyathelo lokuqala kukulungiselela ii-mandrel zesinyithi. Ii-mandrel zesinyithi kufuneka zihambelane nobubanzi bangaphakathi beetyhubhu, kwaye ukuthamba komphezulu wazo kunye nonyango olufanelekileyo lwangaphambi kokuba zisetyenziswe kubalulekile. Ukongeza, ii-mandrel zesinyithi kufuneka ziphathwe ngokufanelekileyo kwangaphambili, njengokucoca nokusebenzisa i-agent yokukhulula, ukuze kube lula inkqubo elandelayo yokuzisusa.

Ngexesha lenkqubo yokusonga ityhubhu, i-metal mandrel idlala indima ebalulekileyo njengoko kufuneka ixhaseukulungiswa kwefayibha yekhabhoniukuqinisekisa ukugoba okuthambileyo. Ke ngoko, ukulungiselela ubungakanani obufanelekileyo be-mandrel yesinyithi kwangaphambili kubalulekile. Ekubeni i-carbon fiber iya kujikeleziswa kumphezulu wangaphandle we-mandrel, ububanzi bangaphandle be-mandrel kufuneka buhambelane nobubanzi bangaphakathi betyhubhu ye-carbon fiber eza kwenziwa.

- Iarhente yokukhulula efaka isicelo

Izinto ezikhuphayo ziyanciphisa ukungqubana kwaye ziqinisekisa ukuba i-demolding igudileyo; kufuneka zifakwe ngokulinganayo kumphezulu we-mandrel. Emva kokuba i-mandrel yesinyithi ilungisiwe, inyathelo elilandelayo kukufaka i-release agent. Izinto ezisetyenziswa rhoqo ziquka i-silicone oil kunye ne-paraffin, ezinciphisa ngempumelelo ukungqubana phakathi kwe-carbon fiber kunye ne-metal mandrel.

Kwi-mandrel yesinyithi elungisiweyo, kufuneka siqinisekise ukuba icocekile ngokupheleleyo kwaye umphezulu uthambile kangangoko ukuze kube lula ukususa imveliso ngokutyibilikayo. Emva koko, i-agent yokukhulula kufuneka isetyenziswe ngokulinganayo kumphezulu we-mandrel.

3. Ukulungiswa kwe-carbon fiber prepreg

- Iintlobo kunye neenzuzo ze-prepreg

Kuphela zizinto ezilungiselela i-carbon fiber ezihlangabezana neemfuno eziphezulu zokuchaneka kokugoba kunye nokulula kokuphatha. Nangona ezinye iintlobo zezinto zokuqinisa, ezifana neendwangu ezomileyo ezifakwe i-epoxy, zingasetyenziswa ngokwethiyori kwinkqubo yokugoba, ekusebenzeni, zizinto ezilungiselela i-carbon fiber kuphela ezinokuhlangabezana neemfuno eziphezulu zokuchaneka kunye nokulula kokuphatha kule nkqubo.

Kule sifundo, sisebenzisa indlela ethile yokulungiselela ukubekwa kweengqimba ukuphucula ukusebenza kwetyhubhu.

- Uyilo lwe-Layup olulungiselelwe kwangaphambili

Umaleko we-prepreg elukiweyo ubekwa kwicala langaphakathi letyhubhu, ulandelwe ziileya ezininzi ze-prepreg elungelelanisiweyo, kwaye ekugqibeleni olunye uleko we-prepreg olulukiweyo lufakwa kwicala langaphandle letyhubhu. Olu yilo lwe-layup lusebenzisa ngokupheleleyo iingenelo ze-fiber orientation ze-prepreg elukiweyo kwi-0° kunye ne-90° axes, nto leyo ephucula kakhulu ukusebenza kwetyhubhu. Uninzi lwee-prepreg ezilungelelanisiweyo ezibekwe kwi-0° axis zinika ukuqina okugqwesileyo kwe-longitudinal kumbhobho.

4. Ukuhamba kwenkqubo yokujika kwepayipi

- Ukulungiselela kwangaphambili ukujika

Emva kokugqiba uyilo lwe-prepreg layup, inkqubo iqhubekela kwinkqubo yokujija imibhobho. Ukulungiswa kwe-prepreg kubandakanya ukususa ifilimu ye-PE kunye nephepha lokukhulula, kunye nokugcina iindawo ezifanelekileyo zokujija. Eli nyathelo libalulekile ekuqinisekiseni ukuqhubela phambili okuthe tye kweenkqubo ezilandelayo zokujija.

- Iinkcukacha zenkqubo yokujika

Ngexesha lenkqubo yokujija, kubalulekile ukuqinisekisa ukujija okuthambileyo kwee-prepregs, kunye ne-metal core shaft ebekwe ngokuthe chu kwaye isetyenziswa ngamandla ngokufanayo. I-metal core shaft kufuneka ibekwe ngokuthe chu kumphetho womaleko wokuqala wee-prepregs, ukuqinisekisa ukusetyenziswa kwamandla ngokulinganayo.

Ngexesha lokusonga, ezinye izinto ezilungiselelwe kwangaphambili zingalinywa eziphelweni ukuze kube lula ukususwa kwemveliso ngexesha lokuyisusa.

- Ukusonga iFilimu yeBOPP

Ukongeza kwi-prepreg, ifilimu ye-BOPP ingasetyenziselwa ukusonga. Ifilimu ye-BOPP yonyusa uxinzelelo lokudibanisa, ikhusela, kwaye ivala i-prepreg. Xa usebenzisa ifilimu yokusonga ye-BOPP, kubalulekile ukuqinisekisa ukudibana okwaneleyo phakathi kweeteyiphu.

5. Inkqubo yokunyanga i-oven

- Ubushushu kunye nexesha lokunyanga

Emva kokusonga ngokuqinileyo izinto eziqinisiweyo ze-prepreg carbon fiber, zithunyelwa kwi-oven ukuze ziyokunyibilika. Ulawulo lobushushu lubalulekile ngexesha lokunyibilika kwi-oven, njengoko ii-prepreg ezahlukeneyo zineemeko ezahlukeneyo zokunyibilika. Eli nyathelo libalulekile ekuqinisekiseni uzinzo lwezinto kunye nokuphucula ukusebenza kwazo.

Ngenxa yobushushu obuphezulu kwi-oven,ifayibha yekhabhonikwaye i-resin matrix isabela ngokupheleleyo, yenze izinto ezidityanisiweyo eziqinileyo.

6. Ukususwa kunye nokuCwangciswa

Emva kokususa ifilimu yokusonga ye-BOPP, imveliso ecociweyo ingasuswa. Ifilimu ye-BOPP ingasuswa emva kokucocwa. Ukuba kuyimfuneko, inkangeleko ingaphuculwa ngokucocwa nokupeyintwa. Ukuze kuphuculwe ubuhle, iinkqubo ezongezelelweyo zokugqiba ezifana nokucocwa nokupeyintwa zingenziwa.

Ixesha lokuthumela: Agasti-11-2025