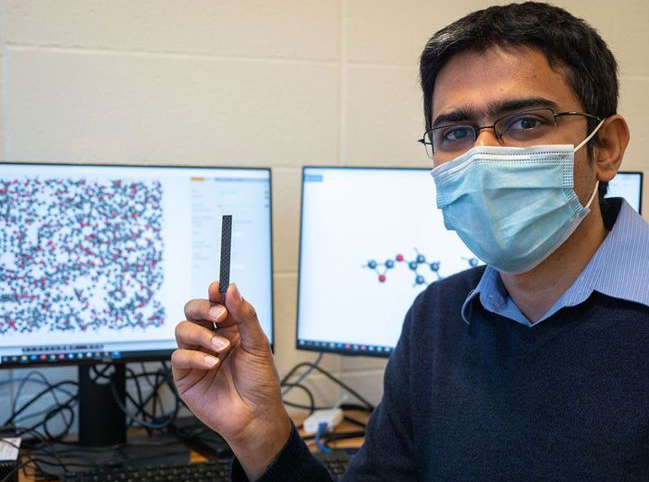

Kwiintsuku ezimbalwa ezidlulileyo, uprofesa weYunivesithi yaseWashington u-Aniruddh Vashisth wapapasha iphepha kwiphephancwadi lehlabathi elinegunya iCarbon, esithi uphumelele ekuphuhliseni uhlobo olutsha lwezinto ezidityanisiweyo ze-carbon fiber. Ngokungafaniyo ne-CFRP yendabuko, engenakulungiswa xa yonakele, izinto ezintsha zinokulungiswa ngokuphindaphindiweyo.

Ngelixa igcina iipropati zoomatshini zezinto zemveli, i-CFRP entsha yongeza inzuzo entsha, oko kukuthi, inokulungiswa ngokuphindaphindiweyo phantsi kwesenzo sobushushu. Ubushushu bungalungisa nawuphi na umonakalo wokudinwa kwezinto, kwaye bungasetyenziselwa ukubola izinto xa kufuneka ziphinde zisetyenziswe ekupheleni komjikelo wenkonzo. Ekubeni i-CFRP yemveli ingenakuphinda isetyenziswe, kubalulekile ukuphuhlisa izinto ezintsha ezinokuphinda zisetyenziswe okanye zilungiswe kusetyenziswa amandla obushushu okanye ukufudumeza irediyo rhoqo.

UNjingalwazi Vashisth uthe umthombo wobushushu unokulibazisa ngokungenammiselo inkqubo yokwaluphala kweCFRP entsha. Ngokuthe ngqo, le nto kufuneka ibizwe ngokuba yiCarbon Fiber Reinforced Vitrimers (vCFRP, Carbon Fiber Reinforced Vitrimers). I-Glass polymer (Vitrimers) luhlobo olutsha lwezinto zepolymer ezidibanisa iingenelo ze-thermoplastic kunye ne-thermosetting plastics ezaqanjwa yisazinzulu saseFransi uNjingalwazi uLudwik Leibler ngo-2011. Izinto zeVitrimers zisebenzisa indlela yokutshintshiselana ngebhondi enamandla, enokwenza ukutshintshiselana ngebhondi yekhemikhali eguqukayo ngendlela enamandla xa ifudunyezwa, kwaye kwangaxeshanye igcine isakhiwo esidityanisiweyo siphela, ukuze iipolymers ze-thermosetting zikwazi ukuziphilisa kwaye ziphinde zicutshungulwe njengeepolymers ze-thermoplastic.

Ngokwahlukileyo koko, izinto ezibizwa ngokuba zizinto ezidityanisiweyo ze-carbon fiber ziizinto ezidityanisiweyo ze-carbon fiber resin matrix (CFRP), ezinokwahlulwa zibe ziintlobo ezimbini: i-thermoset okanye i-thermoplastic ngokwesakhiwo se-resin esahlukileyo. Izinto ezidityanisiweyo ze-thermosetting zihlala ziqulathe i-epoxy resin, iibhondi zeekhemikhali ezinokudibanisa ngokusisigxina izinto zibe ngumzimba omnye. Izinto ezidityanisiweyo ze-thermoplastic ziqulathe ii-resin ezithambileyo ze-thermoplastic ezinokunyibilikiswa kwaye ziphinde zicutshungulwe, kodwa oku kuya kuchaphazela ngamandla kunye nokuqina kwezinto.

Iibhondi zeekhemikhali kwi-vCFRP zinokudityaniswa, ziqhagamshelwe, kwaye ziqhagamshelwe kwakhona ukuze kufunyanwe "umhlaba ophakathi" phakathi kwezinto ze-thermoset kunye nezinto ze-thermoplastic. Abaphandi beprojekthi bakholelwa ukuba iiVitrimers zinokuba yindawo ye-thermosetting resins kwaye ziphephe ukuqokelelana kwezinto ze-thermosetting kwiindawo zokulahla inkunkuma. Abaphandi bakholelwa ukuba i-vCFRP iya kuba lutshintsho olukhulu ukusuka kwizinto zendabuko ukuya kwizinto ezitshintshayo, kwaye iya kuba nefuthe elilandelelanayo ngokweendleko zomjikelo wobomi obupheleleyo, ukuthembeka, ukhuseleko, kunye nokugcinwa.

Okwangoku, iiblade ze-wind turbine yenye yeendawo apho ukusetyenziswa kwe-CFRP kukhulu khona, kwaye ukubuyiswa kweeblade bekusoloko kuyingxaki kweli candelo. Emva kokuphela kwexesha lenkonzo, amawaka eeblade ezisele ziphelelwe lixesha alahlwa kwindawo yokulahla inkunkuma ngendlela yokulahla inkunkuma, nto leyo eyabangela impembelelo enkulu kwindalo esingqongileyo.

Ukuba i-vCFRP ingasetyenziselwa ukwenza iiblade, ingaphinda isetyenziswe kwaye isetyenziswe ngokufudumeza nje. Nokuba iblade elungisiweyo ayinakulungiswa kwaye isetyenziswe kwakhona, ubuncinane inokubola bubushushu. Le nto intsha iguqula umjikelo wobomi obuthe ngqo wee-thermoset composites ibe ngumjikelo wobomi obujikelezayo, oya kuba linyathelo elikhulu eliya kuphuhliso oluzinzileyo.

Ukuba i-vCFRP ingasetyenziselwa ukwenza iiblade, ingaphinda isetyenziswe kwaye isetyenziswe ngokufudumeza nje. Nokuba iblade elungisiweyo ayinakulungiswa kwaye isetyenziswe kwakhona, ubuncinane inokubola bubushushu. Le nto intsha iguqula umjikelo wobomi obuthe ngqo wee-thermoset composites ibe ngumjikelo wobomi obujikelezayo, oya kuba linyathelo elikhulu eliya kuphuhliso oluzinzileyo.

Ixesha lokuthumela: Novemba-09-2021