Inkampani yaseJamani yeHolman Vehicle Engineering isebenzisana namahlakani ukuphuhlisa uphahla oludityanisiweyo olukhaphukhaphu kwizithuthi zikaloliwe.

Le projekthi igxile ekuphuhliseni uphahla lwetram olukhuphisanayo, olwenziwa ngomthwalo owenziwe ngefiber composite materials.Xa kuthelekiswa nesakhiwo sophahla lwendabuko, ubunzima buyancipha kakhulu (minus 40%) kwaye indibano iyancitshiswa uMsebenzi.

Ukongezelela, kuyimfuneko ukuphuhlisa ukuveliswa kwezoqoqosho kunye neenkqubo zokuhlanganisa ezingasetyenziselwa imveliso.Amaqabane eprojekthi yiRCS Railway Components and Systems, Huntscher kunye neFraunhofer Plastics Centre.

"Ukuncitshiswa kokuphakama kophahla kufezekiswa ngokusetyenziswa ngokuqhubekayo kwamalaphu alula kunye noyilo lwesakhiwo kunye nomthwalo ophuculweyo wefiber yeglasi eyomeleziweyo yeendlela zokwakha zeplastiki, kunye nokudityaniswa kwezixhobo ezongezelelweyo kunye nemithwalo ukwazisa ukukhanya okusebenzayo."Umntu ochaphazelekayo uthe.

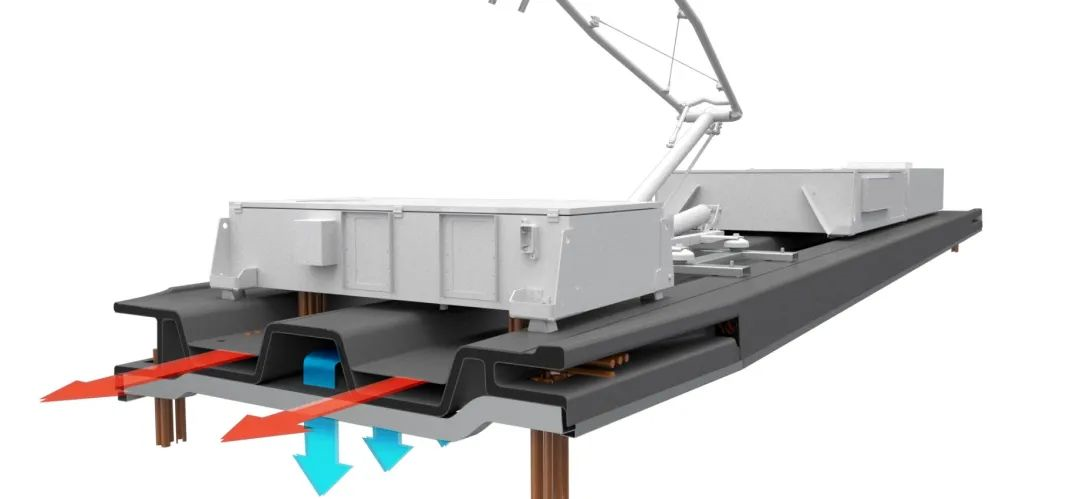

Ngokukodwa iitram zanamhlanje ezisezantsi zineemfuno eziphezulu kakhulu kwisakhiwo sophahla.Oku kungenxa yokuba uphahla alubalulekanga nje kuphela ukuqinisa ukuqina kwesakhiwo sonke sesithuthi, kodwa kwakhona kufuneka kuhlalise imithwalo ephezulu ye-static kunye neguquguqukayo ebangelwa ziiyunithi ezahlukeneyo zezithuthi, ezifana nokugcinwa kwamandla, i-transformer yangoku, i-braking resistor, kunye ne-pantograph , Umoya. iiyunithi zokulungisa kunye nezixhobo zonxibelelwano.

Uphahla olukhaphukhaphu kufuneka luvumele imithwalo ephezulu engashukumiyo kunye neguquguqukayo ebangelwa ziiyunithi ezahlukeneyo zezithuthi

Le mithwalo ephezulu yemishini yenza ukuba isakhiwo sophahla sibe nzima kwaye sibangele ukuba iziko lobunzima besithuthi sikaloliwe liphakame, kubangele ukuziphatha okungahambi kakuhle kunye noxinzelelo oluphezulu kwisithuthi sonke.Ngoko ke, kuyimfuneko ukuphepha ukunyuka kweziko lobunzima besithuthi.Ngale ndlela, kubaluleke kakhulu ukugcina uzinzo lwesakhiwo kunye nokuhambelana kobunzima.

Ukuze ubonise iziphumo zoyilo kunye neeprojekthi zobugcisa, i-RCS iya kuvelisa i-prototypes yokuqala ye-FRP izakhiwo zophahla olulula ekuqaleni konyaka ozayo, kwaye emva koko iqhube iimvavanyo phantsi kweemeko ezibonakalayo kwi-Fraunhofer Plastics Centre.Kwangaxeshanye, uphahla lokubonisa lwaveliswa kunye namaqabane anxulumeneyo kwaye iprototype yadityaniswa kwiimoto zanamhlanje ezikumgangatho ophantsi.

Ixesha lokuposa: Dec-17-2021