Umgangatho we-FRP mold unxulumene ngokuthe ngqo nokusebenza kwemveliso, ingakumbi ngokwezinga lokuguquguquka, ukuqina, njl.njl., ekufuneka kufuneke kuqala. Ukuba awazi ukuba ungawubona njani umgangatho we-mold, nceda ufunde amanye amacebiso kweli nqaku.

1. Ukuhlolwa komphezulu wesikhunta kwenziwa xa sifika, kwaye kufuneka ukuba kungabikho mfanekiso welaphu obonakalayo kumphezulu;

2. Ubukhulu bengubo yejeli yokubumba bukhulu okanye bulingana ne-0.8mm, kwaye ubukhulu bengubo yejeli bubukhulu beleya yengubo yejeli emva kokuyilungisa nokuyibumba, kungekhona ubukhulu befilimu emanzi;

3. Akufanele kubekho i-resin efakwe kumphezulu wekona yesikhunta.

4. Umzimba oyintloko wesikhunta, oko kukuthi, ubushushu bokuguqulwa kobushushu be-laminate ye-FRP, ngokwe-2001 resin parameter ≥110℃.

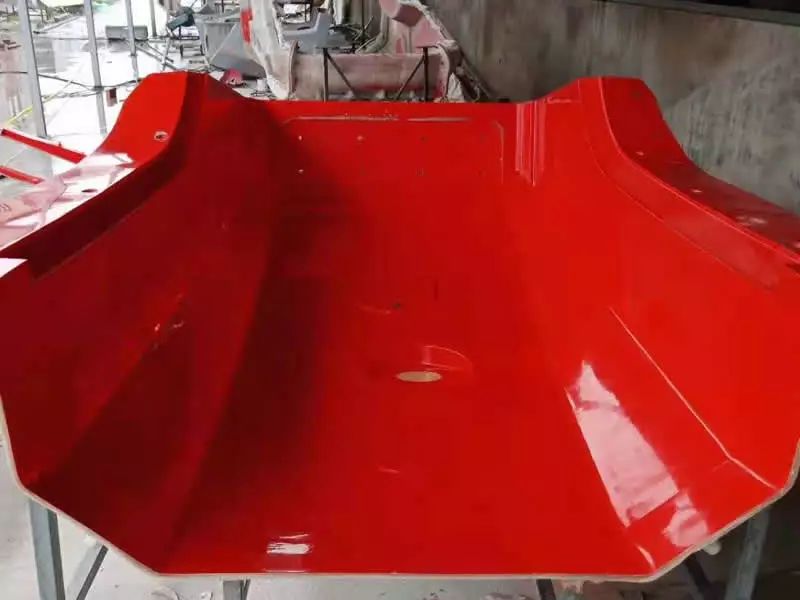

5. Ukukhazimla kunye nokuthe tyaba komphezulu wejeli kuyafuneka ukuze kufikelelwe kumphezulu we-A-level. Kwindawo ethe tye, i-silhouette ingabonakaliswa ngokucacileyo ngaphandle kokuguquka.

6. Iimfuneko zobunzima bomphezulu wejeli: ixabiso eliphakathi lobunzima bebhasi obuyi-10 dispersion points elilinganiswe ngumzimba wesikhunta lingaphezulu kwama-35.

7. Imeko yomphezulu wesikhunta ayifuni maqamza kumphezulu wesikhunta, kungabikho maqamza angaphezu kwama-3 ngaphakathi kwe-1m2 yamaqamza abonakalayo kwi-gel coat kunye ne-mold laminate; akukho zimpawu zebrashi ezicacileyo, imikrwelo kunye namanqaku okulungisa kumphezulu wesikhunta, kwaye kungabikho ngaphezu kwemingxuma emi-5 ngaphakathi kwe-1m2 yomphezulu. A, akunakubakho nto yokubeka iileya.

8. Isakhelo sentsimbi sesikhunta sifanelekile, kwaye kufuneka sibe nesakhiwo sesakhelo siphela. Iqonga lokubambelela kufuneka liqine kwaye lingaguquguquki lula; isixhobo se-hydraulic siyavula kwaye sivale kakuhle nangokulula, isantya siyalungiseka, kwaye kukho iswitshi yokuhamba, enokufikelela amaxesha okuvula nokuvala > amaxesha ali-1000 xa kusetyenziswa ngokwesiqhelo.

9. Isikhunta senziwe ngokwenkqubo yokufunxa imveliso, ubukhulu bomzimba oyintloko buyimfuneko ukufikelela kwi-15mm, kwaye ubukhulu be-flange yesikhunta buyimfuneko ukuba bube yi-≥18mm.

10. Izikhonkwane zokubeka isikhunta ziikhonkwane zesinyithi, kwaye izikhonkwane kunye namacandelo e-FRP kufuneka zivalwe.

11. Umgca wokusika wesikhunta uhlolwa ngokungqongqo ngokwemigangatho yemveliso.

12. Ubungakanani bokufanisa bokubumba kufuneka bube buchanekile, kwaye impazamo yokufanisa phakathi kweendawo ezihambelanayo kufuneka ibe yi-≤1.5mm.

13. Ubomi benkonzo eqhelekileyo yesikhunta akufuneki bube ngaphantsi kweeseti ezingama-500 zeemveliso.

14. Ubuthe tyaba besikhunta buyi ±0.5mm ngemitha nganye ethe tyaba, kwaye akufuneki kubekho ukungalingani.

15. Zonke izilinganiso zesikhunta ziqinisekisiwe ukuba zinempazamo ye-±1mm, kwaye akukho burr kumphezulu we-laminate.

16. Umphezulu wesikhunta awuvumelekanga ukuba ube neziphene ezifana nemingxunya yepinhole, iipateni zepeyinti yeorenji, imikrwelo yesandpaper, imikrwelo yeenyawo zenkukhu, njl.njl., kwaye i-arc kufuneka ibe notshintsho olugudileyo.

17. Isikhunta siyanyangwa emva kokupholisa kubushushu obuphezulu obuyi-80°C, size sisuswe emva kweeyure ezisi-8.

18. Isikhunta asinakuguqulwa phantsi kwemeko yencopho ye-exothermic ye-90℃-120℃, kwaye umphezulu awunakubonakala iimpawu zokuncipha, iintanda, kunye nokungalingani.

19. Kufuneka kubekho umsantsa ongaphezulu kwe-10mm phakathi kwesakhelo sentsimbi kunye nesikhunta, kwaye umdibaniso wemizimba emibini kufuneka ugqunywe nge-cork okanye iibhodi ezinamaleko amaninzi anobukhulu obufanayo.

20. Indawo edibeneyo yesikhunta sokwahlulwa ayinakususwa, uyilo lokubeka isikhunta lufanelekile, isikhunta siyakhululwa, ukusebenza kwemveliso kulula, kwaye isikhunta kulula ukusikhulula.

21. Uxinzelelo olubi olupheleleyo lwesikhunta luxhomekeke kwi-0.1, kwaye uxinzelelo lugcinwa imizuzu emi-5.

Ixesha lokuthumela: Matshi-22-2022