Umgangatho we-FRP mold uhambelana ngokuthe ngqo nokusebenza kwemveliso, ngokukodwa ngokwezinga lokuguqulwa, ukuqina, njl., okufuneka kufuneke kuqala.Ukuba awuyazi indlela yokubona umgangatho wokubumba, ngoko nceda ufunde ezinye iingcebiso kweli nqaku.

1. Ukuhlolwa kwendawo yokubumba kwenziwa xa ifika, kwaye kufuneka ukuba kungabikho iphethini yelaphu ebonakalayo ebusweni;

2. Ubunzima bengubo ye-gel yokubumba bukhulu okanye bulingana no-0.8mm, kwaye ubukhulu bengubo ye-gel bubunzima bengubo yengubo ye-gel emva kokunyanga kunye nokubumba, kungekhona ubukhulu befilimu emanzi;

3. Akufuneki kubekho i-resin deposition phezu kwekona ye-mold.

4. Umzimba oyintloko we-mold, oko kukuthi, ukushisa kwe-thermal deformation ye-FRP laminate, ngokwe-2001 resin parameter ≥110℃.

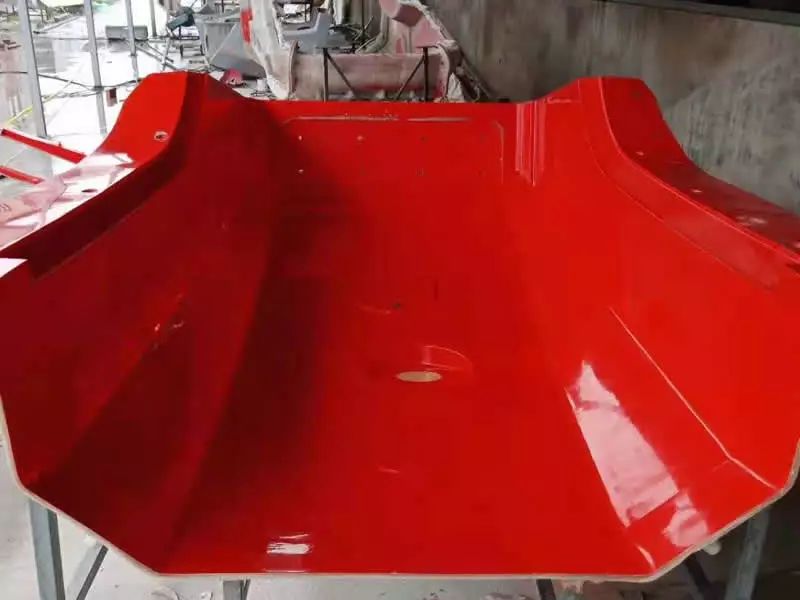

5. I-gloss kunye ne-flatness yobuso bengubo ye-gel iyadingeka ukufikelela kwi-A-level surface.Kwindiza ethe tye, i-silhouette ingabonakaliswa ngokucacileyo ngaphandle kokuguqulwa.

6. Iimfuno zobunzima bomphezulu wengubo yejeli: umyinge wexabiso lobunzima bebhasi yeendawo ezili-10 zokusasazeka ezilinganiswe ngumzimba wokubumba mkhulu kune-35.

7. Isimo somphezulu wesikhunta asifuni iibhubhu ebusweni besikhunta, akukho ngaphezu kwe-3 bubbles ngaphakathi kwe-1m2 yeebhubhu ezibonakalayo kwi-gel coat kunye ne-mold laminate;akukho zimpawu zebrashi ezicacileyo, imikrwelo kunye namanqaku okulungisa kumphezulu wesikhunta, kwaye akukho ngaphezu kwe-5 pinholes ngaphakathi kwe-1m2 yendawo.A, akunakubakho isenzeko sokumaleko.

8. Isakhelo sensimbi yesikhunta sinengqiqo, kwaye kufuneka sibe nesakhiwo sesakhelo ngokubanzi.Iqonga lokubambelela kufuneka liqine kwaye lingakhubazeki lula;isixhobo se-hydraulic sivula kwaye sivale ngokucokisekileyo kwaye ngokucokisekileyo, isantya silungelelaniswa, kunye nokutshintshwa kokuhamba kunikezelwa, okunokuthi kuhlangabezane namaxesha okuvula nokuvala> amaxesha angama-1000 ekusebenziseni okuqhelekileyo.

9. Isikhunta senzelwe ngokwenkqubo ye-vacuum yemveliso, ubukhulu bomzimba oyintloko bufunekayo ukufikelela kwi-15mm, kwaye ubukhulu be-flange ye-mold bufuneka ukuba bube ≥18mm.

10. Izikhonkwane zokumisa isikhunta zizikhonkwane zetsimbi, kwaye izikhonkwane kunye neengxenye ze-FRP kufuneka zitywinwe.

11. Umgca wokusika we-mold uhlolwe ngokungqongqo ngokwemigangatho yemveliso.

12. Ubungakanani obuhambelanayo bokubumba kufuneka buchaneke, kwaye impazamo ehambelanayo phakathi kwamacandelo ahambelanayo kufuneka ibe ≤1.5mm.

13. Ubomi benkonzo eqhelekileyo yesikhunta akufanele ibe ngaphantsi kweesethi ze-500 zeemveliso.

14. I-flatness ye-mold yi-± 0.5mm ngemitha yomgca, kwaye akufanele kubekho ukungalingani.

15. Yonke imilinganiselo yokubumba iqinisekisiwe ukuba ibe nephutha le-± 1mm, kwaye akukho burr ebusweni be-laminate.

16. Umphezulu we-mold awuvumelekanga ukuba ube neziphene ezifana ne-pinholes, iipateni ze-orange peel, i-sandpaper scratches, i-foot foot cracks, njl., kunye ne-arc kufuneka ibe yinguqu egudileyo.

17. Isikhunta emva kokunyangwa kwiqondo lokushisa eliphezulu lama-80 ° C, kwaye idilizwe emva kweeyure ze-8.

18. Umngundo awukwazi ukukhubazeka phantsi kwemeko yencopho ye-90℃-120℃, kwaye umphezulu awunakuvela amanqaku okuncipha, iintanda, kunye nokungalingani.

19. Kufuneka kubekho isithuba esingaphezu kwe-10mm phakathi kwesakhelo sensimbi kunye nesikhunta, kwaye ukudibanisa kwemizimba emibini kufuneka kufakwe i-cork okanye i-multi-layer board of the thickness of same.

20. I-joint of the parting mold ayikwazi ukuchithwa, i-mold positioning design inengqiqo, i-mold ikhutshwe, ukusebenza kwemveliso kulula, kwaye i-mold ilula ukuyikhulula.

21. Uxinzelelo olubi olubi lwe-mold luxhomekeke kwi-0.1, kwaye uxinzelelo lugcinwa imizuzu emi-5.

Ixesha lokuposa: Mar-22-2022